Have you ever wondered why your John Deere electric PTO suddenly stops working when you need it most? It’s frustrating, especially when you rely on your equipment to get important jobs done quickly and efficiently.

Understanding what causes a John Deere electric PTO to fail can save you time, money, and stress. You’ll discover the common reasons behind these failures and how you can prevent them from happening to you. Keep reading to protect your investment and keep your machinery running smoothly.

Common John Deere Electric Pto Issues

The John Deere electric PTO can face several common problems. These issues often cause the PTO to stop working properly. Knowing these problems helps with quick fixes and better maintenance.

Some problems come from the electrical system, while others are mechanical or hydraulic. Each type affects the PTO’s function in different ways.

The electric PTO depends on a good electrical system. Faulty wiring or blown fuses can stop the PTO from engaging. Bad switches or damaged connectors also cause failure. Corrosion on terminals reduces power flow. Regular checks of wires and connections help prevent these issues.

Parts inside the PTO wear out over time. Bearings, gears, and shafts can break or become loose. This wear causes noise, vibration, or complete failure. Lack of lubrication speeds up damage. Routine inspection and oiling extend the PTO life.

Some John Deere electric PTOs use hydraulics for smooth operation. Leaks in hoses or low fluid levels reduce pressure. Clogged filters block fluid flow, affecting PTO performance. Air in the hydraulic system causes erratic movements. Keeping the hydraulic system clean and full avoids these problems.

Electrical System Failures

Electrical system failures are a common reason for John Deere electric PTO problems. These failures stop the PTO from working properly or at all. Understanding the electrical issues helps in quick diagnosis and repair. Many faults come from simple parts that wear out or get damaged over time.

Blown Fuses And Relays

Fuses protect the PTO’s electrical circuit from too much current. A blown fuse breaks the circuit, stopping power flow. Relays act as switches to control the PTO motor. A bad relay can prevent the PTO from turning on. Checking and replacing fuses and relays is a quick fix for many PTO issues.

Faulty Wiring And Connections

Wiring carries electricity from the battery to the PTO motor. Over time, wires can break or corrode. Loose or dirty connections also disrupt the flow of power. Faulty wiring causes intermittent or no power to the PTO. Inspecting wires and cleaning connections often solves the problem.

Battery And Power Supply Issues

The battery provides the power needed for the PTO to work. A weak or dead battery cannot supply enough current. Poor battery terminals or cables reduce power delivery. Regular battery checks and maintenance ensure the PTO gets steady power. Replacing old batteries can restore proper PTO function.

Mechanical Wear And Tear

Mechanical wear and tear is a common reason for John Deere electric PTO failure. Over time, moving parts inside the PTO system suffer from constant use. This causes parts to weaken and stop working properly. Regular maintenance can slow this process. Understanding the key mechanical problems helps in keeping the PTO running smoothly.

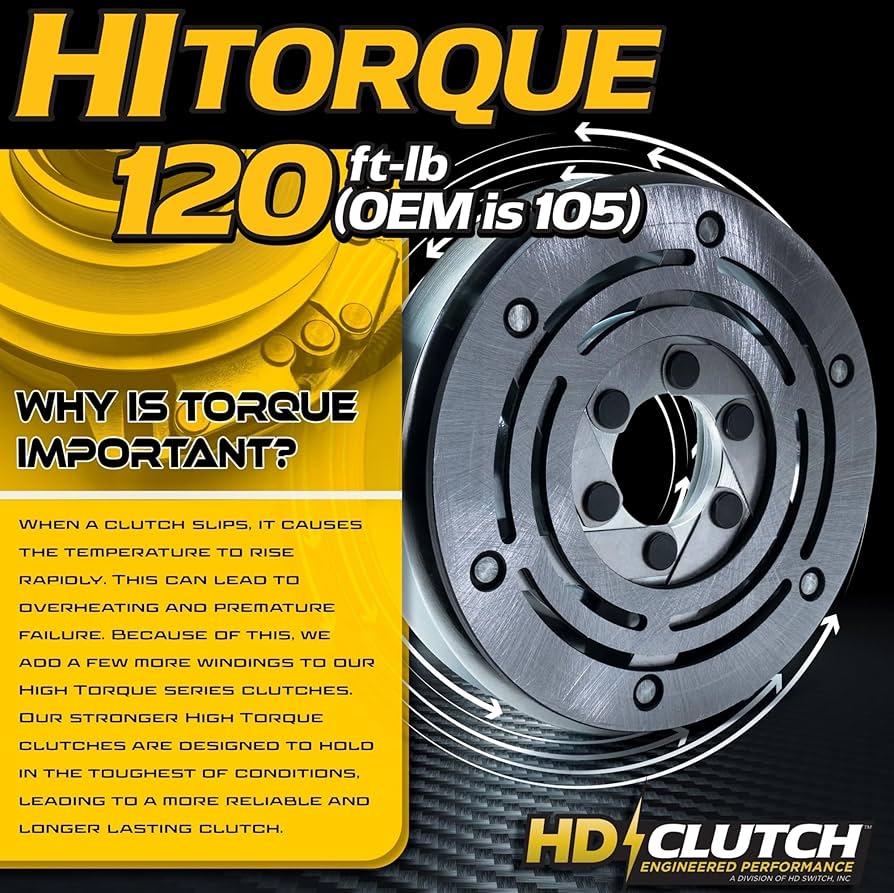

Worn Pto Clutch Components

The PTO clutch engages and disengages the power take-off. Constant use causes clutch plates and springs to wear out. Worn clutch parts slip or fail to engage. This leads to loss of power transfer or sudden stopping. Replacing worn clutch parts on time keeps the PTO working well.

Damaged Gears And Shafts

Gears and shafts inside the PTO transmit power from the tractor to attachments. Over time, heavy loads cause gear teeth to chip or break. Shafts may bend or crack from stress. Damaged gears and shafts cause noise, vibration, and failure. Regular inspection can catch these issues early.

Lack Of Proper Lubrication

Lubrication reduces friction between moving parts in the PTO. Without enough oil or grease, parts grind against each other. This speeds up wear and causes overheating. Lack of lubrication can lead to total PTO failure. Checking and topping up lubricants is essential for smooth PTO operation.

Hydraulic System Problems

The hydraulic system plays a key role in the proper function of a John Deere electric PTO. Problems in this system often cause the PTO to fail. Hydraulic issues reduce power and cause delays. Understanding these problems helps in quick repair and maintenance.

Leaking Hydraulic Lines

Hydraulic lines carry fluid to power the PTO. Leaks in these lines reduce pressure and fluid volume. This leads to weak or no PTO movement. Leaks can come from cracks, loose fittings, or worn seals. Regular checks help catch leaks early.

Faulty Hydraulic Pump

The hydraulic pump generates the pressure needed for the PTO. A faulty pump can cause loss of pressure or no flow at all. Signs include strange noises, overheating, or slow PTO response. Replacing the pump fixes these problems.

Contaminated Hydraulic Fluid

Clean hydraulic fluid is vital for smooth PTO operation. Dirt, water, or metal particles in the fluid cause damage. Contaminated fluid clogs filters and wears out parts. Changing fluid regularly keeps the system healthy and the PTO working well.

Operator Errors Affecting Pto

Operator errors are a common cause of John Deere electric PTO failure. Many problems arise from how the PTO is used. Small mistakes can lead to big damage. Understanding these errors helps prevent costly repairs and downtime.

Proper use of the PTO keeps it working longer. Careless actions can cause the system to break down. Operators must learn the right ways to engage and maintain the PTO. This section explains key operator errors that affect PTO performance.

Incorrect Engagement Techniques

Engaging the PTO incorrectly can cause serious damage. Sudden or rough engagement puts stress on the parts. The PTO clutch can slip or wear out fast. Always engage the PTO smoothly and at the right speed. Avoid forcing the control lever or switching on the PTO while under heavy load.

Overloading The Pto

Overloading the PTO is a frequent mistake. The system has limits on how much power it can handle. Exceeding these limits strains the electric PTO motor and gearbox. This leads to overheating and early failure. Operators should check the equipment’s capacity and avoid pushing the PTO beyond its design.

Ignoring Regular Maintenance

Skipping regular maintenance harms the PTO’s lifespan. Dirt, debris, and worn parts reduce efficiency and cause damage. Regularly inspect and clean the PTO components. Replace worn parts and check electrical connections. Preventive maintenance helps catch issues early and keeps the PTO running smoothly.

Preventing Electric Pto Failures

Preventing electric PTO failures on your John Deere tractor saves time and money. Regular care keeps the PTO working smoothly and avoids costly repairs. Understanding simple steps helps you maintain the system effectively.

Routine Inspection Tips

Check the electric PTO regularly for signs of wear or damage. Look for loose wires, burnt smells, or corrosion around connections. Test the switch to ensure it activates the PTO properly. Catching small problems early prevents bigger failures later.

Proper Maintenance Practices

Keep the electric PTO clean and dry to avoid rust and electrical shorts. Use a soft brush to remove dirt and debris. Apply dielectric grease on connectors to protect from moisture. Follow the tractor’s manual for recommended maintenance schedules.

When To Seek Professional Help

Call a technician if the PTO does not engage or stops suddenly. Strange noises or sparks are signs to get expert service. Complex electrical issues need specialized tools and knowledge. Avoid risking further damage by trying repairs beyond your skill.

Frequently Asked Questions

What Are Common Reasons For John Deere Electric Pto Failure?

Common causes include worn brushes, faulty wiring, and blown fuses. Dirt and moisture can also damage components. Regular maintenance helps prevent these issues and ensures smooth PTO operation.

How Does A Faulty Switch Affect John Deere Pto?

A damaged switch can prevent power transfer to the PTO motor. This stops the PTO from engaging. Replacing or repairing the switch usually resolves the problem quickly.

Can Battery Issues Cause John Deere Electric Pto Failure?

Yes, a weak or dead battery can disrupt power supply to the PTO. This leads to failure in PTO engagement. Ensure the battery is fully charged and connections are secure.

Why Is The Pto Clutch Important In Electric Pto Systems?

The PTO clutch engages and disengages power to the implement. A worn or damaged clutch causes slipping or failure to engage. Regular inspection and replacement maintain efficient PTO function.

Conclusion

A John Deere electric PTO can fail due to many reasons. Common causes include worn-out parts, loose wires, and poor maintenance. Dirt and moisture also harm the system. Regular checks help catch problems early. Fixing small issues prevents bigger damage later.

Understanding these causes keeps your equipment working well. Stay attentive and care for your machine often. This saves time, money, and frustration. Keep your John Deere electric PTO reliable and ready.