If you own a John Deere tractor, you know how important the electric PTO clutch is for smooth operation. But what happens when it doesn’t engage properly or feels off?

Knowing how to adjust your John Deere electric PTO clutch can save you time, prevent damage, and keep your equipment running like new. In this guide, you’ll discover simple, step-by-step instructions to get your PTO clutch working perfectly again. Keep reading to take control of your tractor’s performance and avoid costly repairs down the road.

Tools And Safety Gear Needed

Adjusting a John Deere electric PTO clutch requires the right tools and safety gear. These items protect you and make the job easier. Using proper equipment helps avoid damage to the clutch and tractor parts. Safety gear keeps you safe from injuries during the adjustment process.

Basic Hand Tools

You need simple hand tools like screwdrivers, wrenches, and pliers. A flathead screwdriver helps adjust the clutch screws. Wrenches loosen and tighten bolts on the clutch assembly. Pliers assist in gripping and holding small parts securely.

Multimeter For Electrical Testing

A multimeter checks the electrical components of the PTO clutch. It measures voltage and continuity to find wiring issues. This tool ensures the clutch receives proper electric current for smooth operation.

Protective Gloves

Wear protective gloves to avoid cuts and burns. Gloves protect your hands from hot parts and sharp edges. Choose gloves that fit well and allow good grip.

Eye Protection

Safety glasses shield your eyes from dust and debris. They prevent injuries from flying particles during adjustment. Use clear glasses for better visibility.

Work Light

A bright work light illuminates the clutch area clearly. Good lighting helps you see small parts and screws easily. It reduces mistakes and speeds up the adjustment process.

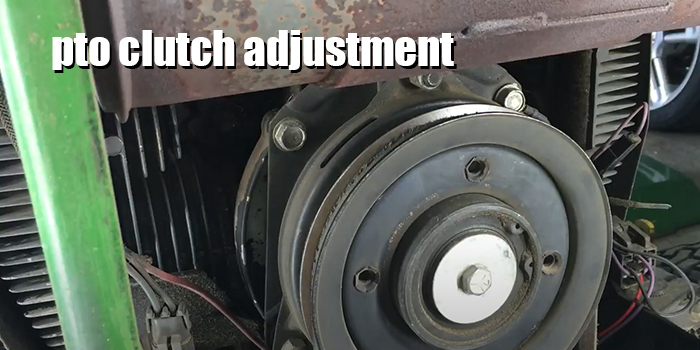

Locating The Pto Clutch

The PTO clutch on a John Deere tractor is found near the engine and transmission. It connects the power to the mower or other attachments. Knowing its location helps in adjusting it correctly for smooth operation.

Understanding The Location Of The Pto Clutch

The PTO clutch is a key part of your John Deere tractor. It controls the power to the mower or other attachments. Finding it is the first step to adjusting it properly.

Usually, the PTO clutch is near the engine. It connects to the mower deck or other powered tools. Knowing where to find it saves time and effort.

Checking Under The Tractor Hood

Open the tractor hood carefully. Look near the engine block for a round metal part. This is often the PTO clutch. It may have wires attached to it.

Look for a belt connected to the clutch. This belt runs to the mower or other equipment. The clutch will be close to where this belt starts.

Using The Owner’s Manual

The owner’s manual shows the exact location of the PTO clutch. It has diagrams and pictures. This guide helps identify parts clearly.

Follow the manual step-by-step. It ensures you do not miss anything important. Manuals are easy to understand and very helpful.

Preparing The Tractor For Adjustment

Start by parking the tractor on a flat surface and turning off the engine. Make sure the key is out and the tractor is cool before adjusting the clutch. Check that all safety locks are in place to avoid accidents.

Park The Tractor On A Flat Surface

Start by parking the tractor on a flat, level surface. This prevents the tractor from rolling during adjustment. Engage the parking brake firmly to keep it stable. Safety first.

Turn Off The Engine And Remove The Key

Switch off the engine completely. Take out the key from the ignition. This stops any accidental starting while you work on the clutch. Stay safe and focused.

Disconnect The Battery

Next, disconnect the battery to cut power to the tractor. This step avoids any electrical accidents. Use a wrench to loosen the battery terminals carefully.

Clean The Area Around The Pto Clutch

Clear dirt and debris near the PTO clutch. Use a brush or cloth to clean the area well. Clean parts help you see better and adjust precisely.

Gather Necessary Tools

Prepare all tools needed for the adjustment. Common tools include wrenches, screwdrivers, and pliers. Having tools ready saves time and avoids interruptions.

Checking The Current Clutch Engagement

Checking the current clutch engagement is the first step in adjusting a John Deere electric PTO clutch. This step helps you understand how well the clutch connects the power from the engine to the mower blades or other attachments.

Proper engagement means the clutch activates smoothly and holds firmly. Poor engagement can cause slipping or uneven power delivery, which lowers performance and may cause damage.

Visual Inspection Of The Clutch

Start by looking at the clutch while the PTO is off. Check for dirt, rust, or wear on the clutch surface. Clean parts work better and last longer.

Testing Clutch Engagement With The Pto Switch

Turn on the PTO switch and watch the clutch engage. It should connect quickly and hold without delay. Any hesitation or slipping means adjustment is needed.

Listening For Unusual Sounds

Listen closely while the clutch engages. Grinding, squealing, or clicking sounds show problems. Normal operation is quiet or has a soft hum.

Checking The Clutch Pad Wear

Remove the clutch cover if needed. Look at the clutch pads for wear or thinning. Worn pads reduce grip and cause slipping during use.

Measuring Clutch Air Gap

Use a feeler gauge to measure the air gap between the clutch plates. The correct gap ensures proper engagement and prevents slipping.

Adjusting The Pto Clutch

Adjusting the John Deere electric PTO clutch is important for smooth operation. Proper adjustment helps the clutch engage and disengage correctly. This prevents damage and extends the clutch’s life. Follow these steps carefully to adjust the clutch safely and effectively.

Loosening The Adjustment Bolts

Start by locating the adjustment bolts on the clutch assembly. Use the correct size wrench or socket to loosen these bolts. Loosen them just enough to allow movement. Do not remove the bolts completely. This step prepares the clutch for proper clearance setting.

Setting The Proper Clutch Clearance

Check the clearance between the clutch plate and the flywheel. Use a feeler gauge to measure the gap. The correct clearance is usually specified in the John Deere manual. Adjust the clutch plate until the clearance matches the recommended value. This adjustment ensures the clutch engages smoothly.

Tightening The Bolts Securely

After setting the clearance, tighten the adjustment bolts firmly. Use the wrench or socket to secure them in place. Make sure bolts are tight enough to prevent movement. Avoid over-tightening to prevent damage. Proper tightening keeps the clutch setting stable during operation.

Testing The Pto Clutch Operation

Testing the PTO clutch operation is a key step in adjusting a John Deere electric PTO clutch. This process confirms if the clutch engages and disengages properly. It ensures safe and efficient tractor use. Skipping this step might cause damage or unsafe conditions.

Follow these steps carefully to check the PTO clutch operation. Test in a safe area, with the tractor off and the parking brake set. Always wear safety gear and keep hands clear of moving parts.

Preparing For The Pto Clutch Test

Start by placing the tractor on a flat surface. Engage the parking brake to prevent movement. Turn off the engine and remove the key. Check that the PTO switch is in the off position. Remove any debris around the PTO area.

Engaging The Pto Clutch

Turn the tractor key to the on position without starting the engine. Switch the PTO control to the “on” position. Listen for a click or hum, which shows the clutch is engaging. The PTO shaft should start to turn slowly. If it does not, adjustment or repair might be needed.

Disengaging The Pto Clutch

Turn the PTO switch to the off position. The clutch should release immediately. The PTO shaft must stop turning quickly. If it continues to move, the clutch may be sticking or misadjusted. Repeat the test a few times to confirm consistent operation.

Troubleshooting Common Issues

Troubleshooting common issues with a John Deere electric PTO clutch helps keep your equipment running smoothly. Problems may cause poor performance or damage if ignored. Understanding symptoms leads to quick fixes and less downtime.

Clutch Slipping

Clutch slipping means the PTO shaft spins without power transfer. This issue lowers efficiency and can harm other parts. Check if the clutch adjustment is loose or worn out. Tighten the adjustment screw carefully to reduce slipping. Inspect the friction plates for wear and replace if needed. Dirt or oil on plates also causes slipping. Clean the clutch surface with a suitable cleaner.

Clutch Not Engaging

If the clutch does not engage, the PTO will not activate. First, verify the electrical connections are secure and clean. Weak battery voltage may prevent clutch engagement. Test the battery and wiring for faults. The solenoid or relay might be defective and require replacement. Inspect the clutch coil for damage or burning. Adjust the clutch clearance to ensure proper contact.

Unusual Noises

Strange sounds from the clutch signal mechanical problems. Grinding or squealing noises often indicate worn bearings or loose parts. Lubricate the clutch components according to the manual. Check for broken springs or damaged plates inside the clutch. Tighten any loose bolts or screws to eliminate rattling. Address unusual noises quickly to avoid serious damage.

Maintenance Tips For Pto Clutch

Keeping your John Deere electric PTO clutch in good shape helps it work better and last longer. Regular maintenance stops problems before they start. It also makes sure your tractor runs safely and smoothly.

Simple care steps keep the clutch clean and adjusted right. Check parts often and fix small issues fast. This saves time and money on big repairs later.

Cleaning The Pto Clutch

Dirt and debris can cause the clutch to slip or wear out fast. Use a soft brush or cloth to clean the clutch surface. Avoid using water or harsh chemicals that can damage parts.

Checking For Wear And Tear

Look at the clutch for cracks, burns, or worn spots. Replace any damaged parts quickly. Worn parts lower performance and can cause failure.

Adjusting The Clutch Cable

Check the clutch cable tension often. A loose cable can make the clutch slip. Tighten the cable so the clutch engages smoothly without dragging.

Lubricating Moving Parts

Apply light grease to the clutch’s moving parts. This reduces friction and stops rust. Use only the lubricant recommended by John Deere.

Testing Clutch Engagement

Start the tractor and engage the PTO. Listen for unusual noises and watch for smooth operation. If it feels rough or slips, adjust or service the clutch.

Frequently Asked Questions

How Do You Know When The Pto Clutch Needs Adjustment?

You may notice slipping, unusual noise, or delayed engagement. These signs indicate the clutch needs tightening or realignment. Regular inspection prevents damage and ensures efficient operation.

What Tools Are Required To Adjust A John Deere Electric Pto Clutch?

Basic tools include a wrench, screwdriver, and a feeler gauge. These help loosen bolts, adjust clearance, and check alignment precisely for optimal clutch performance.

How Do You Safely Disconnect Power Before Adjusting The Pto Clutch?

Always turn off the tractor and remove the key. Disconnect the battery to prevent accidental engagement and ensure your safety during adjustment.

Can Adjusting The Pto Clutch Improve Tractor Performance?

Yes, proper adjustment ensures smooth power transfer and prevents clutch slipping. This results in better efficiency, longer clutch life, and improved tractor operation.

Conclusion

Adjusting a John Deere electric PTO clutch is simple with the right steps. Check the clutch often to keep it working well. Tighten or loosen the clutch as needed for smooth operation. Use basic tools and follow safety rules during adjustments.

Regular care helps avoid bigger problems later. Keep your tractor running strong and ready for work. Small fixes now save time and money in the future. Stay patient and careful for the best results.