Have you ever wondered how your John Deere tractor powers attachments without wasting fuel or making extra noise? Understanding how a John Deere electric PTO works can change the way you use your equipment.

This simple yet powerful feature gives you more control, saves energy, and boosts your tractor’s efficiency. Keep reading, and you’ll discover exactly how this technology can make your work easier and more productive.

John Deere Electric Pto Basics

The John Deere Electric PTO basics explain how this system powers equipment. It is a key feature for many tractors. The electric PTO makes starting and stopping the power take-off easier. It uses electricity instead of a manual lever or pedal. This modern design improves safety and convenience during operation.

Core Components

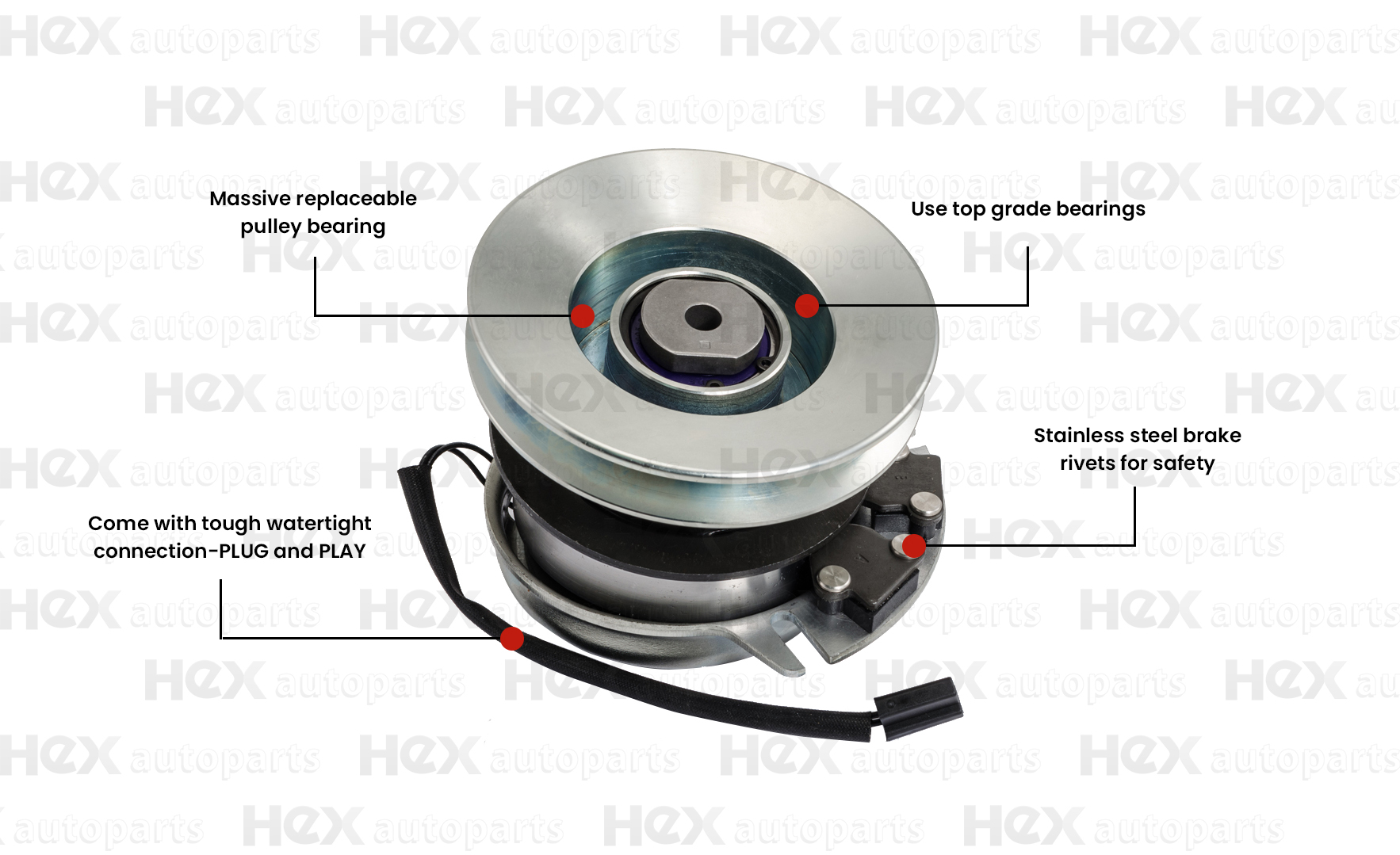

The electric PTO system has several main parts. There is an electric switch inside the tractor cab. This switch controls the PTO engagement. A relay acts as a bridge between the switch and the PTO clutch. The PTO clutch itself connects to the tractor’s engine. It transfers power to attached equipment like mowers or balers.

Wiring connects all these parts, allowing electric signals to flow. The system also includes safety features to prevent accidents. Sensors monitor the PTO status and engine speed. These components work together to ensure smooth and safe operation.

Functionality Overview

The operator activates the PTO by flipping the electric switch. This sends a signal to the relay. The relay then powers the PTO clutch to engage. The clutch connects the engine’s power to the PTO shaft. The shaft rotates and drives the attached equipment.

Stopping the PTO is simple. The operator turns off the switch. The relay cuts power to the clutch, disengaging the PTO. This quick response improves control and safety. The electric PTO allows for easy on/off control without leaving the seat.

Activation Mechanism

The activation mechanism of a John Deere electric PTO controls how the power take-off starts and stops. This system uses electrical signals rather than mechanical levers. It makes PTO engagement smooth and precise. The operator can easily control the PTO from the tractor’s cabin.

The mechanism connects the tractor’s electrical system to the PTO clutch. When the operator presses the PTO switch, an electrical current activates the clutch. This action transfers power from the engine to the attached implements.

Engaging The Pto

To engage the PTO, the operator flips a switch or presses a button. This sends electricity to an electromagnetic clutch. The clutch then locks the PTO shaft to the tractor’s engine power.

The electric activation avoids sudden jerks that can damage equipment. It allows for a smooth start, reducing wear on the tractor and implements. The system also permits variable speed control for certain models.

Safety Features

John Deere electric PTOs include safety features to prevent accidents. The system stops power automatically if the operator leaves the seat. It also cuts power if the tractor’s speed drops too low.

These safety measures protect both the operator and the equipment. The electric PTO won’t engage unless all conditions are safe. This reduces the risk of injury or damage during operation.

Power Transmission Process

The power transmission process in a John Deere Electric PTO moves energy from the tractor to the attached tool. It turns electric power into mechanical force. This process ensures tools like mowers or balers work efficiently. The system controls power smoothly, avoiding sudden starts or stops. This control protects both the tractor and the tool.

Understanding this process helps users operate their equipment better. It also helps in maintaining the system for longer use.

Electric Motor Role

The electric motor is the heart of the PTO system. It converts electricity into rotational motion. This motion drives the PTO shaft connected to the tool. The motor provides steady power without using fuel. This makes the system cleaner and quieter. The motor’s design allows quick starts and stops. This precision helps protect the tool from damage.

Torque And Speed Control

The system adjusts torque and speed to match the tool’s needs. It uses sensors to measure load and speed. The control unit changes electric current to manage power. This keeps the tool running at the right speed. It prevents stalling or overworking the motor. Smooth power delivery saves energy and reduces wear. Operators get better control and safer operation.

Advantages Over Hydraulic Ptos

John Deere electric PTOs offer clear benefits over traditional hydraulic PTOs. These advantages make electric PTOs a preferred choice for many users. The benefits include better efficiency and easier maintenance. Both factors save time and reduce costs on the farm.

Efficiency Gains

Electric PTOs use power directly from the tractor’s battery. This direct power source reduces energy loss during operation. Electric PTOs start and stop instantly. This quick response cuts down on fuel use. Operators get precise control over the power output. This control helps match power to the task easily. Less energy waste means better fuel economy. It also lowers emissions, which is good for the environment.

Maintenance Benefits

Electric PTOs have fewer moving parts than hydraulic systems. This simplicity lowers the chance of mechanical failure. No hydraulic fluid means no leaks or messy cleanups. Checking the system is faster and easier. Electric PTOs require less regular service. This reduces downtime and repair costs. Operators spend more time working and less time fixing. The reliability of electric PTOs improves overall tractor performance.

Common Applications

The John Deere electric PTO powers many farm machines. It provides smooth and reliable power transfer. This makes farm work easier and faster. Farmers use it for many tasks. The electric PTO is easy to control. It helps save time and effort in the field.

Compatible Implements

The electric PTO works with many tools. It fits mowers for cutting grass. It also runs rotary tillers for soil work. Seeders and spreaders use the PTO power too. Some sprayers depend on the PTO for operation. Balers and snow blowers can connect to it. This wide range makes it very useful on farms.

Field Usage Examples

Farmers use the electric PTO to mow large fields fast. It powers tillers to prepare soil for planting. The PTO runs spreaders to spread fertilizer evenly. It also helps seeders place seeds accurately. Sprayers use it to apply pesticides safely. In winter, snow blowers connected to the PTO clear paths quickly. These are just some ways farmers use it.

Troubleshooting Tips

Troubleshooting a John Deere electric PTO can save time and money. Understanding common problems helps you fix issues fast. Many problems are easy to spot and solve. This section covers simple tips to keep your PTO working well.

Common Issues

The electric PTO may fail to engage or disengage properly. Sometimes the PTO switch stops working. Loose wires or blown fuses are frequent causes. Overheating can also cause the PTO to shut off. Dirt and rust may block the PTO clutch from moving smoothly.

Simple Fixes

Check the PTO switch for damage or dirt. Clean the switch contacts if needed. Inspect all wiring connections for looseness or breaks. Replace blown fuses with the correct type. Allow the PTO to cool if it overheats before trying again. Lubricate the clutch to remove rust and debris. These easy steps often restore PTO function quickly.

Frequently Asked Questions

How Does A John Deere Electric Pto Activate?

A John Deere electric PTO activates via a switch inside the tractor cab. It uses an electric signal to engage the PTO clutch. This system offers quick, safe, and efficient control over PTO operations, improving overall functionality and ease of use.

What Powers A John Deere Electric Pto System?

The John Deere electric PTO system is powered by the tractor’s electrical system. It draws power from the battery and alternator to operate the PTO clutch electronically. This setup ensures consistent and reliable PTO engagement without manual effort.

Can A John Deere Electric Pto Improve Fuel Efficiency?

Yes, a John Deere electric PTO can improve fuel efficiency. It allows precise control of PTO speed and engagement. This reduces unnecessary engine load and fuel consumption during PTO operations, making it more economical for farming tasks.

Is The John Deere Electric Pto Safe To Use?

The John Deere electric PTO includes safety features like automatic disengagement and overload protection. These features prevent accidental operation and protect the tractor and operator. It enhances workplace safety during PTO-driven tasks.

Conclusion

A John Deere electric PTO uses electricity to control power output. It helps run equipment safely and smoothly. The system offers easy on and off control with a switch. This makes work faster and reduces effort. Understanding how it works can improve tractor use.

Keep your machine maintained for best results. Electric PTOs bring convenience to many farming tasks. Simple technology, clear benefits, and reliable performance. A smart choice for farmers who want ease and safety.