For Nordson glue machine troubleshooting, check for clogged nozzles and ensure proper temperature settings. Inspect hoses for leaks and replace damaged parts.

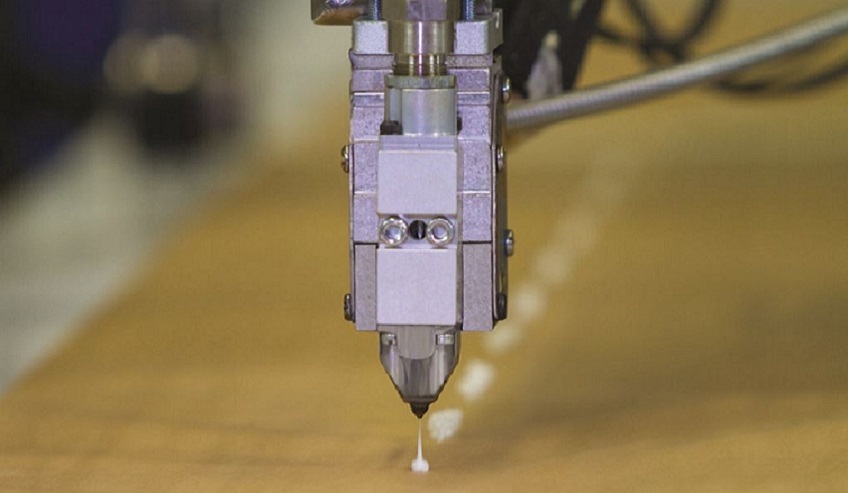

Nordson glue machines are essential for precise adhesive application in various industries. Regular maintenance and timely troubleshooting can prevent downtime and ensure optimal performance. Common issues include clogged nozzles, temperature inconsistencies, and hose leaks. Addressing these problems quickly can maintain production efficiency and product quality.

Proper training for operators and routine inspections can also reduce the likelihood of machine malfunctions. By understanding the machine’s components and their functions, you can easily identify and fix issues. Implementing a proactive maintenance schedule will extend the lifespan of your Nordson glue machine. Keep your operations running smoothly with these practical troubleshooting tips.

Credit: www.youtube.com

Common Issues

Nordson glue machines are reliable but can have common issues. Here, we discuss common problems and their solutions.

Glue Not Dispensing

One common issue is when the glue does not dispense. This can halt production and waste time.

- Check the nozzle: Ensure it is not clogged.

- Inspect the hose: Look for kinks or blockages.

- Verify the glue level: Make sure there is enough glue in the tank.

Use the following table to troubleshoot this issue:

| Possible Cause | Solution |

|---|---|

| Clogged Nozzle | Clean the nozzle with a proper cleaner. |

| Blocked Hose | Replace or clean the hose. |

| Low Glue Level | Refill the glue tank. |

Inconsistent Glue Flow

Another issue is inconsistent glue flow. This can affect the quality of your product.

- Adjust the pressure: Ensure the pressure settings are correct.

- Examine the glue temperature: Verify it is within the recommended range.

- Check the filter: Clean or replace the filter if it is dirty.

Here are some steps to fix inconsistent glue flow:

1. Adjust the pressure to the manufacturer’s settings.

2. Ensure the glue temperature is within 160-180°C.

3. Clean the filter to remove any debris.

By following these steps, you can solve many Nordson glue machine issues efficiently.

Machine Calibration

Proper calibration of your Nordson glue machine ensures it runs efficiently. This process involves adjusting various settings like temperature and pressure. Accurate calibration can prevent issues and enhance performance.

Adjusting Temperature

Temperature settings are crucial for glue consistency.

Follow these steps to adjust the temperature:

- Locate the temperature control panel.

- Set the desired temperature using the control knob.

- Monitor the display to ensure it reaches the set level.

Incorrect temperature can cause glue to harden or remain too liquid.

Setting Pressure Levels

Pressure levels impact the glue flow rate.

Steps to set pressure levels:

- Find the pressure adjustment knob.

- Turn the knob to increase or decrease pressure.

- Check the pressure gauge to confirm the setting.

Proper pressure ensures a smooth and even glue application.

Glue Quality

Ensuring glue quality is vital for optimal machine performance. Poor quality glue can cause issues.

Choosing The Right Glue

Selecting the right glue is the first step. Different tasks need different glues.

- Hot Melt Adhesives: Ideal for packaging and assembly.

- Pressure Sensitive Adhesives: Best for labels and tapes.

- Reactive Adhesives: Suitable for high-strength bonds.

Choose a glue that matches the task. This ensures strong bonds and efficient use.

Storage Best Practices

Proper glue storage is crucial for maintaining quality. Follow these tips:

- Temperature Control: Store at recommended temperatures.

- Sealed Containers: Keep glue in airtight containers.

- Avoid Moisture: Moisture can degrade glue quality.

Check the table below for ideal storage conditions:

| Glue Type | Temperature Range | Humidity Level |

|---|---|---|

| Hot Melt Adhesives | 60-80°F | Low Humidity |

| Pressure Sensitive Adhesives | 50-70°F | Low Humidity |

| Reactive Adhesives | 70-90°F | Moderate Humidity |

Maintaining the right storage conditions preserves glue effectiveness.

Credit: www.nordson.com

Maintenance Tips

Maintaining your Nordson glue machine ensures its longevity and optimal performance. Routine maintenance helps prevent breakdowns and saves costs in the long run. Follow these simple tips to keep your machine running smoothly.

Cleaning Procedures

Regular cleaning is vital for your Nordson glue machine. Follow these steps:

- Turn off and unplug the machine.

- Remove excess glue with a scraper or cloth.

- Use a soft brush to clean the nozzles.

- Wipe all surfaces with a damp cloth.

- Ensure the machine is completely dry before use.

Cleaning prevents clogs and ensures smooth glue flow. Make it a habit to clean the machine after each use.

Replacing Worn Parts

Regularly check for worn parts. Replace them promptly to avoid machine failure. Here are common parts to inspect:

| Part | Signs of Wear | Replacement Frequency |

|---|---|---|

| Nozzles | Clogging, irregular glue flow | Every 6 months |

| Hoses | Cracks, leaks | Annually |

| Filters | Clogs, reduced pressure | Every 3 months |

Keeping a stock of spare parts ensures quick replacement. Follow the manufacturer’s guide for part replacements.

Error Codes

Understanding error codes is crucial for effective troubleshooting of Nordson glue machines. These codes help identify problems quickly and accurately. The ability to interpret and resolve these errors can minimize downtime and maintain productivity.

Interpreting Codes

Error codes can sometimes seem confusing. Each code corresponds to a specific issue. Here’s how to interpret them:

- E01 – Sensor malfunction

- E02 – Glue blockage

- E03 – Temperature error

- E04 – Motor failure

Refer to the machine’s manual for a full list of codes. Each code has a detailed description and suggested solutions.

Common Fixes

Here are some common fixes for frequent error codes:

| Error Code | Possible Fix |

|---|---|

| E01 | Check and replace faulty sensors. |

| E02 | Clear any glue blockages in the system. |

| E03 | Adjust temperature settings to correct levels. |

| E04 | Inspect and repair or replace the motor. |

Always ensure the machine is turned off before attempting repairs. Safety first!

For persistent issues, contact Nordson’s customer support. They provide expert assistance and service.

Operator Training

Proper operator training is crucial for effective Nordson glue machine troubleshooting. Well-trained operators can quickly identify and fix issues, ensuring minimal downtime.

Essential Skills

Operators must possess essential skills to operate Nordson glue machines:

- Understanding the machine’s manual and controls

- Basic troubleshooting techniques

- Routine maintenance procedures

- Knowledge of common error codes

Safety Protocols

Safety is paramount when operating Nordson glue machines. Operators should follow strict safety protocols:

- Always wear protective gear

- Ensure the machine is turned off before maintenance

- Follow lockout/tagout procedures

- Regularly check for leaks or damaged parts

| Skill | Description |

|---|---|

| Machine Manual Knowledge | Reading and understanding the Nordson machine manual. |

| Troubleshooting Techniques | Identifying and fixing common issues. |

| Maintenance Procedures | Performing routine maintenance tasks. |

| Safety Protocols | Following safety guidelines and protocols. |

Advanced Troubleshooting

Advanced troubleshooting ensures your Nordson glue machine runs smoothly. This guide helps you diagnose and fix complex issues. Follow these steps to troubleshoot and maintain your machine.

Diagnosing Electrical Issues

Electrical issues can halt your Nordson glue machine. Start by checking the power supply. Ensure all cables are connected securely. Use a multimeter to test voltage levels. Check for blown fuses and replace them if necessary.

Inspect the control panel for error codes. These codes provide clues about the problem. Refer to the machine’s manual for code meanings. If the issue persists, look at the wiring. Damaged wires can cause electrical failures.

Here are some steps to follow:

- Check the power supply and connections.

- Use a multimeter to measure voltage.

- Inspect and replace blown fuses.

- Refer to error codes in the manual.

- Inspect wiring for damage.

Software Updates

Software updates can resolve many issues. Always keep your machine’s software up-to-date. Check the Nordson website for the latest updates. Follow these steps to update the software:

- Visit the Nordson website.

- Download the latest software update.

- Transfer the update to a USB drive.

- Insert the USB drive into the machine’s USB port.

- Follow the on-screen instructions to complete the update.

Updating the software can improve performance and fix bugs. It ensures your machine operates efficiently.

Credit: www.hbfuller.com

Expert Advice

Troubleshooting a Nordson Glue Machine can be tricky. Our expert advice helps you fix problems fast. Follow these tips to keep your machine running smoothly.

When To Call A Professional

Sometimes, you can’t fix the problem alone. Here are signs it’s time to call a professional:

- Unusual noises: Strange sounds may indicate serious issues.

- Frequent clogs: Persistent clogs need expert help.

- Electrical issues: Sparks or flickering lights require a technician.

- Leakage: Glue leaking from unexpected places needs immediate attention.

Professionals have the tools and knowledge to fix these problems. Don’t risk further damage by trying to fix serious issues yourself.

Preventative Measures

Prevent problems by taking these steps:

- Regular cleaning: Clean your machine after each use to prevent clogs.

- Check for wear and tear: Inspect parts regularly for signs of damage.

- Use proper materials: Always use the recommended glue and parts.

- Calibrate settings: Ensure settings are correct for your tasks.

These measures help your machine work better and last longer. Keep a maintenance schedule to ensure everything runs smoothly.

| Issue | Preventative Measure |

|---|---|

| Clogs | Clean regularly |

| Wear and Tear | Inspect parts |

| Incorrect Settings | Calibrate often |

Following these tips can save you time and money. Keep your Nordson Glue Machine in top shape with regular care and attention.

Frequently Asked Questions

How To Purge A Nordson Glue Gun?

Purge a Nordson glue gun by heating it to operating temperature. Then, trigger the gun to dispense old adhesive. Repeat until the flow is clear.

How To Clean A Hot Melt Glue Tank?

Turn off and unplug the glue tank. Let it cool down. Use a scraper to remove excess glue. Apply a suitable cleaning solvent. Wipe clean with a cloth.

How To Fix Nordson Glue Machine Errors?

Start by checking the user manual for error codes. Ensure all connections are secure. Clean the nozzles and filters. If the problem persists, contact Nordson customer support.

Why Is My Nordson Glue Machine Not Heating?

Check the power supply and ensure it is properly connected. Inspect the heating elements for any damage. Replace faulty components as needed.

Conclusion

Mastering Nordson glue machine troubleshooting ensures smooth operations and minimizes downtime. Regular maintenance is key to avoiding issues. Follow these tips to keep your machine running efficiently. Proper care saves time and resources. Implement these strategies for optimal performance and long-term reliability.

Stay proactive and enjoy hassle-free production processes.