The Atlas Copco Air Compressor Troubleshooting PDF provides solutions for common compressor issues. It helps users maintain optimal performance.

Atlas Copco air compressors are known for their reliability and efficiency. Yet, like any machinery, they can encounter problems. The troubleshooting PDF is an essential resource for users, offering step-by-step solutions to common issues. It covers topics like pressure drops, overheating, and unusual noises.

The guide is designed for easy understanding, making it accessible to both novices and experienced technicians. By following the instructions, users can quickly diagnose and fix problems, ensuring minimal downtime. This proactive approach helps in maintaining the compressor’s longevity and performance. Regular maintenance and timely troubleshooting keep operations running smoothly.

Basic Troubleshooting Steps

Having trouble with your Atlas Copco air compressor? Don’t worry! Below are some basic troubleshooting steps to help you get back on track. Follow these simple steps to diagnose and fix common issues.

Initial Checks

Before diving deep into troubleshooting, start with these initial checks:

- Check the Power Supply: Ensure the compressor is plugged in and the power switch is on.

- Inspect Fuses and Circuit Breakers: Replace blown fuses or reset tripped breakers.

- Verify Air Filters: Clean or replace clogged air filters.

Safety Precautions

Always prioritize safety when troubleshooting your air compressor. Follow these safety precautions:

- Turn Off Power: Always turn off and unplug the compressor before inspecting.

- Wear Safety Gear: Use gloves and safety glasses to protect yourself.

- Release Pressure: Ensure all air pressure is released before opening any part.

Following these steps can help you diagnose common issues quickly and safely. Always refer to the Atlas Copco air compressor troubleshooting PDF for detailed instructions.

Electrical Problems

Electrical problems in an Atlas Copco air compressor can halt operations. Understanding these issues can save time and money. The two main categories of electrical problems are power supply issues and motor malfunctions.

Power Supply Issues

Power supply issues are a common problem. Ensure the air compressor is connected to a reliable power source. Use a voltmeter to check voltage levels. They should match the compressor’s specifications.

- Voltage Drops: Low voltage can cause the compressor to malfunction. Check for voltage drops in the power supply.

- Loose Connections: Inspect all electrical connections. Loose wires can cause interruptions in power supply.

- Blown Fuses: Replace any blown fuses immediately. Fuses protect the compressor from electrical surges.

Inconsistent power supply can damage the compressor. Regular checks can prevent major issues.

Motor Malfunctions

Motor malfunctions are another major issue. The motor is the heart of the compressor. If it fails, the compressor stops working.

- Overheating: Overheating can damage the motor. Ensure proper ventilation around the compressor.

- Burnt Windings: Burnt windings indicate an electrical fault. Inspect the motor windings for any burns.

- Noise: Unusual noise can signal motor problems. Listen for any abnormal sounds.

Regular maintenance can prevent motor malfunctions. Always follow the manufacturer’s guidelines for maintenance.

| Issue | Solution |

|---|---|

| Voltage Drops | Check and stabilize power supply |

| Loose Connections | Secure all electrical connections |

| Blown Fuses | Replace fuses immediately |

| Overheating | Ensure proper ventilation |

| Burnt Windings | Inspect and repair motor windings |

| Noise | Listen for abnormal sounds |

Mechanical Issues

Mechanical issues in Atlas Copco air compressors can halt operations. Understanding these problems ensures smooth functioning and longevity. This section highlights common mechanical problems and solutions.

Pressure Problems

Pressure problems are common in air compressors. Low pressure can disrupt tasks. High pressure can damage tools and machinery. Here’s a table summarizing common pressure issues and their solutions:

| Issue | Possible Cause | Solution |

|---|---|---|

| Low Pressure | Blocked filter | Clean or replace the filter |

| High Pressure | Malfunctioning pressure switch | Replace the pressure switch |

| Fluctuating Pressure | Leaks in the system | Inspect and seal leaks |

Unusual Noises

Unusual noises indicate mechanical issues in air compressors. Identifying these noises can prevent further damage. Common noises and their potential causes include:

- Banging: Loose components

- Squealing: Worn belts

- Hissing: Air leaks

Addressing these noises early can save time and money. Regular maintenance checks are crucial for identifying and fixing these issues.

Credit: www.academia.edu

Air Quality Concerns

Air quality concerns are critical when using Atlas Copco air compressors. Poor air quality can lead to equipment damage and production downtime. This section will cover common issues like moisture in air lines and oil contamination.

Moisture In Air Lines

Moisture in air lines can cause significant problems. Rust and corrosion in the system are common issues. Here’s how to identify and resolve moisture concerns:

- Check the air dryer for proper function.

- Inspect filters for water buildup.

- Ensure drain valves are operating correctly.

Maintaining dry air is crucial for system efficiency. Use a table for quick reference:

| Component | Action |

|---|---|

| Air Dryer | Check for proper function |

| Filters | Inspect for water buildup |

| Drain Valves | Ensure they operate correctly |

Oil Contamination

Oil contamination in the air lines can lead to severe issues. It can ruin end products and damage equipment. Follow these steps to identify and fix oil contamination:

- Check the oil separator for wear and tear.

- Inspect the air filters for oil residue.

- Ensure proper oil levels in the compressor.

Proper maintenance is essential to avoid oil contamination. Use quality filters and regularly check oil levels.

Maintenance Tips

Maintaining your Atlas Copco air compressor is crucial for its longevity. Regular maintenance prevents costly repairs and downtime. Below are key maintenance tips to keep your air compressor in top shape.

Routine Inspections

Regular inspections help identify potential issues before they become serious. Follow these steps for effective routine checks:

- Check oil levels weekly.

- Inspect air filters monthly.

- Ensure belts and hoses are in good condition.

- Listen for unusual noises during operation.

- Verify pressure settings are correct.

Component Replacements

Replacing worn-out components is essential for optimal performance. Use the table below for a quick guide:

| Component | Replacement Interval |

|---|---|

| Air Filters | Every 3 months |

| Oil | Every 6 months |

| Belts | Annually |

| Hoses | Annually |

Regular maintenance ensures your compressor runs smoothly. Follow these tips to extend your equipment’s life.

Credit: courses.air-compressor-guide.com

Using The Troubleshooting Pdf

Struggling with your Atlas Copco air compressor? The Atlas Copco Air Compressor Troubleshooting PDF is a valuable resource. It helps users diagnose and resolve common issues quickly and efficiently.

Accessing The Guide

Accessing the troubleshooting guide is simple. First, visit the Atlas Copco website. Navigate to the support section. There, you will find the PDF available for download.

Alternatively, you can search for the guide online. Use keywords like “Atlas Copco air compressor troubleshooting PDF”. Ensure you download from a reputable source.

Navigating The Content

Once you have the PDF, open it on your device. The guide is well-organized and easy to navigate. You will find a table of contents at the beginning. This helps you quickly locate the issue you are facing.

The guide is divided into sections. Each section addresses specific problems. These include:

- Compressor not starting

- Low pressure output

- Unusual noises

- Overheating issues

Each problem is explained in detail. The guide provides step-by-step instructions. Follow these steps to troubleshoot and fix the issue.

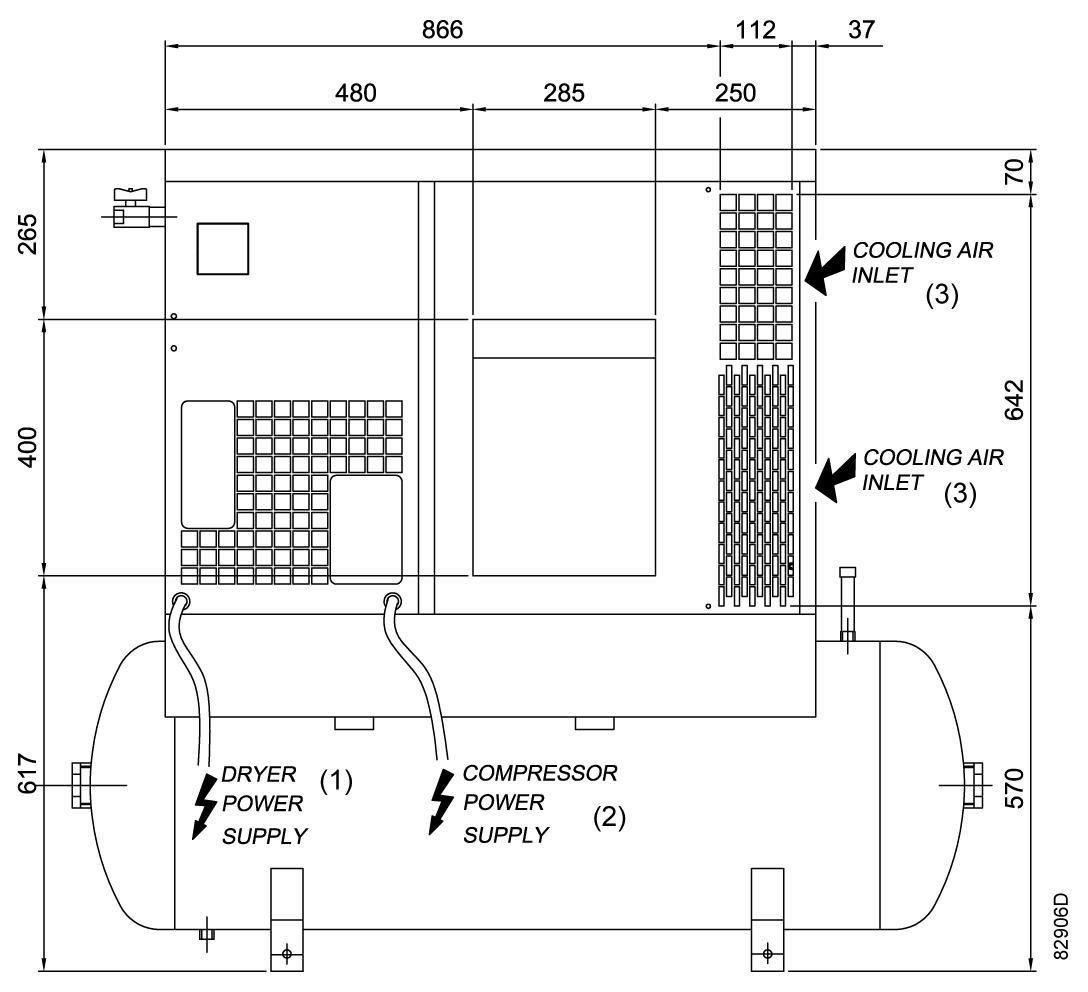

For quick reference, many guides also include diagrams. These visual aids make it easier to understand the instructions.

| Issue | Possible Cause | Solution |

|---|---|---|

| Compressor not starting | Power supply issue | Check power connections |

| Low pressure output | Blocked air filter | Clean or replace filter |

| Unusual noises | Loose parts | Tighten components |

| Overheating issues | Inadequate ventilation | Improve airflow |

By using the troubleshooting PDF, you can save time and money. It reduces the need for professional repair services. Ensure your air compressor runs smoothly and efficiently.

When To Seek Professional Help

Understanding when to seek professional help for your Atlas Copco air compressor is crucial. Timely intervention can save both time and money. Let’s explore the signs that indicate severe issues and how to find the right technician.

Identifying Severe Issues

Some problems require immediate professional attention. Here are key indicators:

- Unusual Noises: Loud or strange sounds mean severe mechanical problems.

- Constant Overheating: Frequent overheating can signal serious internal issues.

- Low Pressure Output: If pressure drops, there could be a significant leak.

- Frequent Shutdowns: Regular shutdowns might indicate electrical faults.

Finding A Technician

Locating a skilled technician is essential for resolving complex issues. Follow these steps:

- Research: Look for certified Atlas Copco technicians.

- Check Reviews: Read online reviews for reliable service feedback.

- Ask for Quotes: Get multiple quotes to compare services and prices.

- Verify Credentials: Ensure the technician has proper certification.

Proper troubleshooting ensures your air compressor runs smoothly. If in doubt, always seek professional help.

Credit: tommycarwash.zendesk.com

Frequently Asked Questions

How Do You Fix An Air Compressor That Won’t Start?

Check the power supply, reset the circuit breaker, inspect the pressure switch, and ensure the tank pressure is below cut-in level.

Why Is My Air Compressor Not Getting Pressure?

Your air compressor may not be getting pressure due to leaks, faulty valves, or a damaged pressure switch. Check for air leaks, inspect valves, and ensure the pressure switch functions properly. Regular maintenance can prevent these issues.

What Are The Faults In Compressor?

Common compressor faults include overheating, oil leaks, electrical issues, valve failures, and pressure inconsistencies. Regular maintenance helps prevent these problems.

How Do You Troubleshoot A Defective Compressor?

To troubleshoot a defective compressor, check for power supply issues, inspect refrigerant levels, listen for unusual noises, verify thermostat settings, and test the capacitor.

Conclusion

Understanding your Atlas Copco air compressor is crucial for efficient maintenance. Our troubleshooting PDF simplifies the process. Regularly check and address issues to ensure longevity. Use this guide to keep your equipment running smoothly. Stay proactive to avoid costly repairs.

Download the PDF and keep it handy for quick reference.