For accurate Ice O Matic troubleshooting, consult the manual’s error codes and follow the step-by-step diagnostic procedures provided. Address common issues like water supply problems and temperature fluctuations.

Ice O Matic ice machines are reliable but can encounter issues that disrupt their performance. Troubleshooting these machines efficiently ensures minimal downtime and optimal functionality. The manual offers detailed guidance on diagnosing and fixing common problems. Key areas of focus include checking water supply connections, monitoring temperature controls, and ensuring proper electrical connections.

Regular maintenance and understanding error codes can prevent frequent issues. Users can resolve many problems themselves by following the manual’s instructions. This proactive approach helps maintain the machine’s efficiency and longevity, ensuring a consistent supply of ice.

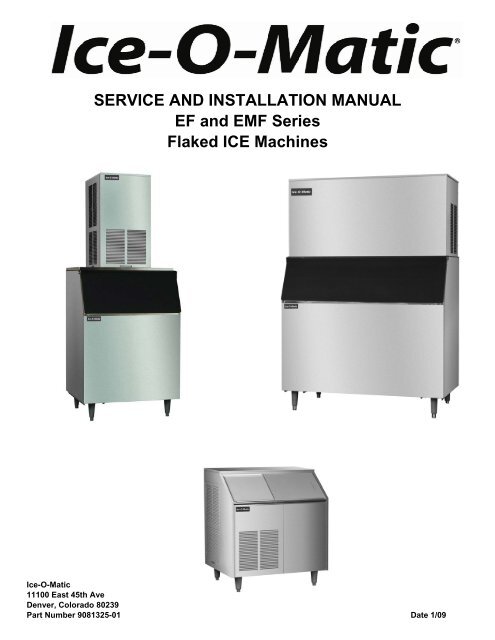

Credit: www.yumpu.com

Understanding Ice O Matic Components

The Ice O Matic ice machines are complex. They contain many parts that work together to produce ice. Knowing these parts helps you fix problems easily. This guide breaks down each component and its function.

Key Parts Breakdown

Here are the key parts of an Ice O Matic machine:

- Compressor: Compresses refrigerant gas.

- Condenser: Cools the refrigerant gas to liquid.

- Evaporator Plate: Freezes water into ice.

- Water Pump: Circulates water over the evaporator plate.

- Thermostat: Controls the temperature.

- Ice Bin: Stores the ice.

Component Functions

Each part of the Ice O Matic machine has a specific job:

| Component | Function |

|---|---|

| Compressor | Compresses refrigerant gas for cooling. |

| Condenser | Cools and liquefies refrigerant gas. |

| Evaporator Plate | Turns water into ice cubes. |

| Water Pump | Moves water over the evaporator plate. |

| Thermostat | Regulates the machine’s temperature. |

| Ice Bin | Stores the produced ice. |

Understanding these parts helps you troubleshoot better. Knowing their functions makes repair easier and faster.

Initial Troubleshooting Steps

When your Ice O Matic machine stops working, knowing the initial troubleshooting steps can save you time and stress. This guide will help you identify and resolve common issues. Follow these steps carefully to keep your machine in top condition.

Safety Precautions

Before starting, ensure you follow these safety precautions:

- Unplug the machine from the power source.

- Wear safety gloves to protect your hands.

- Ensure the area around the machine is dry.

- Read the machine’s manual for specific warnings.

Basic Checks

Perform these basic checks to identify simple issues:

- Power Supply: Verify that the machine is properly plugged in.

- Water Supply: Ensure the water valve is open and water is flowing.

- Filters: Check if the water filter is clean and not clogged.

- Ice Bin: Make sure the ice bin is not full or blocked.

| Component | Check | Action |

|---|---|---|

| Power Cord | Inspect for damage | Replace if frayed |

| Water Line | Ensure it’s connected | Reattach if loose |

| Ice Maker | Listen for unusual noises | Contact a technician |

If these steps do not resolve the issue, consult the Ice O Matic troubleshooting manual for advanced diagnostics. Always refer to the manual for detailed instructions.

Water Supply Issues

Ice O Matic ice machines need a consistent water supply to work well. Water supply issues can cause poor ice production or machine failure. This section will help you identify and fix common water supply problems.

Checking Water Lines

First, ensure the water lines are connected properly. Loose or disconnected lines can halt ice production. Inspect the connections for any leaks or blockages.

- Turn off the water supply.

- Check for any visible leaks.

- Ensure all connections are tight and secure.

Use a flashlight to inspect the water lines for any kinks. Kinks can restrict water flow. Straighten out any kinks you find.

If the water lines are damaged, replace them immediately. Use only Ice O Matic recommended parts for replacements.

Addressing Low Water Pressure

Low water pressure can affect ice production. It can cause smaller ice cubes or no ice at all. Test the water pressure to ensure it meets the machine’s requirements.

- Turn off the ice machine.

- Disconnect the water supply line.

- Use a pressure gauge to measure the water pressure.

The ideal water pressure for Ice O Matic machines is between 20-80 psi. If the pressure is too low, consider the following steps:

| Possible Issue | Solution |

|---|---|

| Clogged Filter | Replace the water filter. |

| Main Water Supply | Check the main water line for issues. |

| Pressure Regulator | Ensure the regulator is working properly. |

If these steps don’t resolve the issue, you may need professional help. Contact a certified technician for further assistance.

Credit: www.yumpu.com

Ice Production Problems

Ice production problems can be frustrating for any business. These issues can affect customer satisfaction and operational efficiency. Understanding and troubleshooting ice production issues is crucial for maintaining a smooth operation.

Inconsistent Ice Output

Inconsistent ice output can be a common issue. It can stem from various causes. Here are some steps to diagnose and fix this problem:

- Check the water supply: Ensure the water supply is consistent. Low water pressure can disrupt ice production.

- Inspect the water filter: A clogged filter can reduce water flow. Replace the filter if needed.

- Examine the temperature: The ambient temperature should be within the recommended range. Too high or too low temperatures can affect ice production.

No Ice Production

No ice production is a critical issue. It requires immediate attention. Follow these steps to troubleshoot:

- Check the power supply: Ensure the ice maker is plugged in. Verify the power switch is on.

- Inspect the water line: Ensure the water line is not kinked. Check for any blockages.

- Examine the ice bin: The ice bin should not be full. If full, empty it to allow new ice production.

- Test the thermostat: A faulty thermostat can halt ice production. Replace it if necessary.

If the above steps do not resolve the issue, refer to the Ice O Matic Troubleshooting Manual for further guidance.

Electrical And Mechanical Failures

Understanding electrical and mechanical failures in your Ice O Matic machine is crucial. These issues can halt operations and cause frustration. In this section, we will delve into common problems and solutions.

Power Supply Issues

Power supply issues are common in ice machines. Here’s how to troubleshoot:

- Check if the machine is plugged in properly.

- Inspect the power cord for any damage.

- Ensure the outlet is working by testing with another device.

- Look at the circuit breaker. Has it tripped?

- Verify the voltage matches the machine’s requirements.

Use a multimeter to check the electrical flow. This can help identify any issues.

Motor And Compressor Problems

The motor and compressor are essential for ice production. Here’s a guide to troubleshoot:

- Listen for unusual noises from the motor.

- Check if the compressor is overheating.

- Inspect for oil leaks around the compressor.

- Ensure the fan is running smoothly.

- Look at the condenser coils. Are they clean?

If the motor or compressor fails, consider these steps:

- Turn off the machine to prevent further damage.

- Consult the Ice O Matic troubleshooting manual.

- Contact a professional technician if needed.

Regular maintenance can prevent many motor and compressor issues.

Cleaning And Maintenance Tips

Proper cleaning and maintenance of your Ice O Matic machine ensure it works efficiently. Neglecting these tasks can lead to poor performance and costly repairs. Follow these simple steps to keep your machine in top shape.

Regular Cleaning Routine

Regular cleaning is vital for optimal performance. Ensure to clean your machine at least once a month.

- Turn off the ice maker and unplug it.

- Remove and discard all ice from the bin.

- Use a soft cloth and warm soapy water to clean the interior.

- Rinse thoroughly to remove any soap residue.

- Dry all components with a clean, dry towel.

Descaling Procedures

Scale buildup can affect ice quality. Descale your machine every six months.

- Turn off the ice maker and unplug it.

- Remove all ice and water from the machine.

- Mix a descaling solution according to the manufacturer’s instructions.

- Pour the solution into the water reservoir.

- Run the machine through a complete cycle.

- Discard the ice produced during this cycle.

- Rinse the machine thoroughly with clean water.

- Run two more cycles with fresh water to remove any descaling solution.

- Resume normal operation.

Refer to the table below for a quick reference on cleaning and descaling intervals:

| Task | Frequency |

|---|---|

| Regular Cleaning | Monthly |

| Descaling | Every Six Months |

Advanced Troubleshooting

Ice-O-Matic machines are built to last. Sometimes, they face issues that need advanced troubleshooting. This section helps you with error codes and knowing when to call a professional.

Error Codes Interpretation

Ice-O-Matic machines show error codes when there’s a problem. Understanding these codes is crucial. They help you fix the issue quickly.

- E1: High-temperature error. Check the thermostat and cooling system.

- E2: Water supply error. Ensure water flows freely to the machine.

- E3: Ice sensor error. Inspect and clean the ice sensor.

- E4: Ice storage bin error. Ensure the bin is not full or blocked.

When To Call A Professional

Sometimes, troubleshooting can be challenging. Here are signs you need a professional:

- Repeated Errors: If errors keep showing up, call for expert help.

- Complex Repairs: Issues with the compressor or motor need a technician.

- Electrical Problems: Never handle electrical issues alone. It’s dangerous.

- Warranty Concerns: Fixing it yourself might void the warranty. Check first.

Knowing when to call a professional can save time and prevent damage. Always prioritize safety.

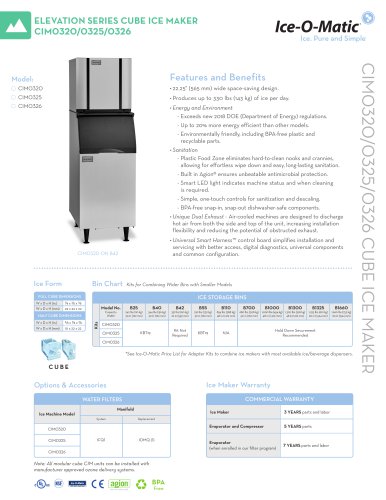

Credit: pdf.archiexpo.com

Preventative Measures

Ice-O-Matic machines are essential for businesses that rely on a steady supply of ice. To keep your machine running smoothly, it’s important to take some preventative measures. These steps can help you avoid costly repairs and downtime.

Routine Inspections

Regular inspections are crucial for maintaining your Ice-O-Matic machine. Check the following areas frequently:

- Water Supply: Ensure there are no leaks.

- Filters: Replace filters every six months.

- Electrical Connections: Look for any loose wires.

By performing these checks, you can identify issues early.

Best Practices

Implementing best practices will extend the life of your Ice-O-Matic machine. Follow these tips:

- Clean the Machine: Clean the ice bin weekly.

- Sanitize Regularly: Use a food-safe sanitizer monthly.

- Monitor Performance: Keep an eye on ice production rates.

These practices help maintain efficiency and prevent malfunctions.

| Inspection Task | Frequency |

|---|---|

| Check Water Supply | Weekly |

| Replace Filters | Every 6 Months |

| Inspect Electrical Connections | Monthly |

| Clean Ice Bin | Weekly |

| Sanitize Machine | Monthly |

By adhering to these preventative measures, you can ensure your Ice-O-Matic machine runs efficiently.

Frequently Asked Questions

Where Is The Reset Button On The Ice-o-matic Ice Machine?

The reset button on the Ice-O-Matic ice machine is typically located behind the front panel or near the control board.

What Do The Lights Mean On The Ice-o-matic Ice Machine?

The lights on an Ice-O-Matic ice machine indicate its status. Green means it’s operating normally. Yellow signals a potential issue or maintenance need. Red indicates a serious problem requiring immediate attention.

Why Is My Ice-o-matic Ice Machine Not Making Ice?

Your Ice-O-Matic ice machine may not be making ice due to a clogged filter, low water pressure, or a malfunctioning thermostat. Check for blockages, ensure proper water flow, and inspect the thermostat settings. Regular maintenance can prevent these issues.

Why Is The Red Light Flashing On My Ice Machine?

The red light on your ice machine might indicate a malfunction or maintenance issue. Check the manual for specific error codes. Ensure the water supply is on and filters are clean. If problems persist, contact customer support for assistance.

Conclusion

Mastering Ice O Matic troubleshooting can save time and money. Regular maintenance ensures optimal performance. Follow our guide to address common issues. This manual empowers you to tackle problems with confidence. Keep your ice machine running smoothly and efficiently. Happy troubleshooting and enjoy continuous ice production!