To troubleshoot a Stahls Hotronix heat press, check for proper temperature settings and ensure even pressure distribution. Inspect electrical connections and replace any damaged parts.

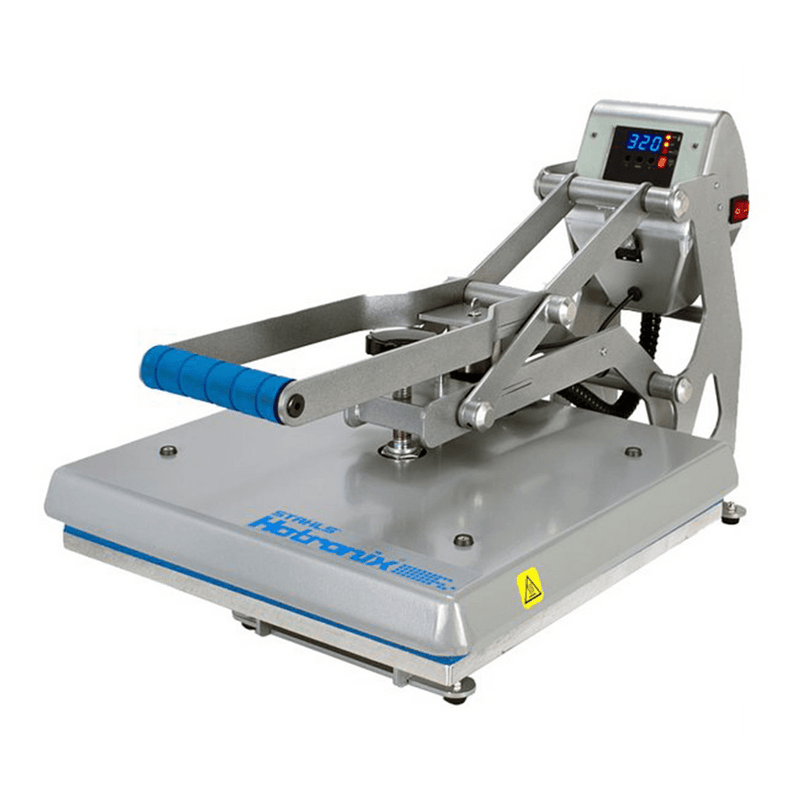

Stahls Hotronix heat presses are renowned for their reliability, but like any equipment, they can encounter issues. Common problems include inconsistent temperature, uneven pressure, and electrical faults. Regular maintenance and proper usage can prevent many of these issues. It’s crucial to regularly check temperature settings, ensure even pressure, and inspect electrical connections.

Replacing worn or damaged components promptly can also help maintain optimal performance. By following these steps, you can keep your Stahls Hotronix heat press running smoothly and avoid costly downtime. Always refer to the user manual for specific troubleshooting tips and solutions.

Credit: www.heatpressnation.com

Common Heat Press Issues

The Stahls Hotronix heat press is a reliable machine. Yet, users often face common issues. These problems can disrupt production. Addressing them can save time and effort.

Temperature Problems

Incorrect temperature settings can ruin your designs. Always preheat the press. Make sure to use a reliable thermometer.

- Inconsistent Heat: Check the heating element. Replace it if needed.

- Overheating: Allow the press to cool down. Check the thermostat.

- Underheating: Increase the temperature. Ensure the press reaches the set temperature.

Pressure Inconsistencies

Pressure issues can affect the final product. Always check the pressure settings. Adjust according to the material.

- Too Much Pressure: This can cause damage. Reduce the pressure setting.

- Too Little Pressure: This can result in incomplete transfers. Increase the pressure setting.

- Uneven Pressure: Check the platen. Ensure it is level.

| Issue | Solution |

|---|---|

| Inconsistent Heat | Check and replace the heating element. |

| Overheating | Check thermostat settings. |

| Underheating | Increase temperature setting. |

| Too Much Pressure | Reduce pressure setting. |

| Too Little Pressure | Increase pressure setting. |

| Uneven Pressure | Level the platen. |

Credit: www.stahls.com

Error Codes And Meanings

Understanding error codes on your Stahls Hotronix Heat Press is crucial. These codes help diagnose issues quickly, ensuring minimal downtime. Below, we explain common error codes and their meanings.

Code E1

The Code E1 error indicates a problem with the temperature sensor. This error usually means the machine can’t read the temperature accurately.

To troubleshoot:

- Check the temperature sensor connections.

- Inspect the sensor wire for damage.

- Ensure the sensor is placed correctly.

If the problem persists, you may need to replace the temperature sensor. This error is critical, as it can affect press performance.

Code E2

The Code E2 error signifies an overheating issue. This error means the heat press temperature is too high, posing a safety risk.

To troubleshoot:

- Turn off the heat press immediately.

- Let the machine cool down completely.

- Check for any blockages in the airflow.

- Inspect the heating element for damage.

- Restart the machine after ensuring all is clear.

If the Code E2 error returns, consider contacting customer support. Operating with this error can damage your machine.

These steps should help resolve common error codes on your Stahls Hotronix Heat Press. For persistent issues, professional assistance is advisable.

Temperature Calibration Tips

Accurate temperature calibration is vital for the optimal performance of your Stahls Hotronix Heat Press. Ensuring the temperature is correct helps achieve consistent, high-quality results. Here, we’ll explore essential tips to calibrate your machine effectively.

Using A Pyrometer

A pyrometer is a reliable tool for measuring the heat press temperature. Here are the steps to use it:

- Turn on your heat press and set it to the desired temperature.

- Allow the machine to reach the set temperature.

- Place the pyrometer sensor on the heat platen surface.

- Read the temperature displayed on the pyrometer.

Compare this reading with your heat press’s display. If there’s a significant difference, calibration is needed.

Adjusting Thermostat

If your heat press temperature is off, you may need to adjust the thermostat. Follow these steps:

- Turn off the heat press and unplug it.

- Locate the thermostat adjustment screw, usually found at the back of the control box.

- Turn the screw slightly to increase or decrease the temperature.

- Plug in and turn on the heat press.

- Use the pyrometer to check the new temperature.

Repeat the adjustment until the pyrometer reading matches the set temperature on the heat press.

| Step | Description |

|---|---|

| 1 | Turn off and unplug the machine. |

| 2 | Locate and adjust the thermostat screw. |

| 3 | Turn on the machine and check temperature. |

| 4 | Repeat adjustment if needed. |

Proper calibration ensures your heat press operates at the correct temperature, producing perfect transfers every time.

Pressure Adjustments

Understanding pressure adjustments in your Stahls Hotronix Heat Press is crucial. Proper pressure ensures your transfers are perfect. Here’s how to set the correct pressure and deal with uneven pressure.

Setting Correct Pressure

Setting the correct pressure on your heat press is simple. Follow these steps:

- Turn on your heat press machine.

- Place the material and transfer on the platen.

- Adjust the pressure knob to the desired level.

- Lock down the press and check the pressure gauge.

Ensure the pressure matches the transfer’s requirements. Use the pressure guide in the manual for reference.

Dealing With Uneven Pressure

Uneven pressure can ruin your transfers. Follow these tips to resolve it:

- Check the platen for any debris.

- Ensure the material is evenly placed.

- Adjust the pressure knob to balance the pressure.

- Test with a small transfer to verify.

If the problem persists, inspect the machine for wear and tear. Regular maintenance can prevent uneven pressure issues.

| Problem | Solution |

|---|---|

| Platen misalignment | Realign the platen |

| Debris on platen | Clean the platen |

| Worn pressure knob | Replace the knob |

Regular inspection and cleaning can help maintain your heat press. Ensure all parts are in good condition for even pressure.

Maintenance Practices

Maintaining your Stahls Hotronix Heat Press ensures a longer lifespan and better performance. Implementing proper maintenance practices is crucial for optimal functionality. Below are some key practices to keep your heat press in top condition.

Cleaning The Heat Plate

The heat plate is the core component of your heat press. Keeping it clean ensures even heat distribution and prevents residue build-up. Follow these steps to clean the heat plate:

- Turn off the machine and unplug it.

- Allow the heat plate to cool completely.

- Use a soft, damp cloth to wipe off any residue.

- For stubborn stains, use a mild detergent.

- Wipe the plate dry with a clean, soft cloth.

Avoid using abrasive materials. These can damage the surface of the heat plate.

Lubricating Moving Parts

Lubrication is essential for the smooth operation of your heat press. Regularly lubricating the moving parts reduces friction and wear. Here’s how to do it:

- Identify the moving parts that need lubrication.

- Use a high-quality lubricant suitable for heat press machines.

- Apply a small amount of lubricant to the moving joints and hinges.

- Wipe off any excess lubricant with a clean cloth.

- Operate the press a few times to distribute the lubricant evenly.

Regular lubrication prevents squeaking and ensures smooth operation.

| Maintenance Task | Frequency |

|---|---|

| Cleaning the Heat Plate | Weekly |

| Lubricating Moving Parts | Monthly |

By following these maintenance practices, you can ensure your Stahls Hotronix Heat Press remains in excellent condition. Regular upkeep will enhance its performance and longevity.

Electrical Issues

Experiencing electrical issues with your Stahls Hotronix Heat Press can be frustrating. These problems can halt your production and cause delays. This section will guide you through troubleshooting electrical issues. This guide covers two crucial steps: checking the power supply and inspecting wiring.

Checking Power Supply

First, ensure your heat press is properly plugged in. Check the outlet for power. You can do this by plugging in another device. If the device works, the outlet has power.

Next, inspect the power cord for damage. Look for frays, cuts, or burns. Damaged power cords can cause electrical issues. If you find damage, replace the power cord immediately.

Use a multimeter to check the power supply’s voltage. Make sure the voltage matches the heat press requirements. Incorrect voltage can lead to malfunctions.

Inspecting Wiring

Open the heat press carefully to inspect the internal wiring. Loose or disconnected wires can cause electrical issues. Use a screwdriver to check the connections.

Look for burnt or damaged wires. Replace any damaged wires you find. Ensure all connections are tight and secure.

Check for signs of overheating. Overheating can damage the wiring. If you find any signs, let the press cool before using it again.

Follow these steps to troubleshoot electrical issues with your Stahls Hotronix Heat Press. Keeping your equipment in good condition ensures smooth operation.

Software Updates

Software updates are essential for maintaining the performance of your Stahls Hotronix Heat Press. Regular updates ensure that your machine runs smoothly and efficiently. Below, we’ll guide you through the process of downloading updates and installing firmware.

Downloading Updates

First, visit the official Stahls Hotronix website. Navigate to the support section. Look for the latest software update for your heat press model.

Ensure your internet connection is stable. Click on the download link. Save the update file to your computer.

- Open your web browser.

- Go to the Stahls Hotronix website.

- Find the support section.

- Locate the software update.

- Click download.

- Save the file.

Installing Firmware

After downloading the update, locate the saved file. Connect your heat press to your computer using a USB cable.

Open the update file. Follow the on-screen instructions to install the firmware. Ensure the installation completes without interruption.

- Find the downloaded file.

- Connect the heat press to the computer.

- Open the update file.

- Follow the installation steps.

- Wait for the process to finish.

After installation, restart your heat press. This ensures the new firmware is fully integrated. Your Stahls Hotronix Heat Press should now be up-to-date.

| Step | Action |

|---|---|

| 1 | Visit the Stahls Hotronix website |

| 2 | Navigate to the support section |

| 3 | Download the update file |

| 4 | Connect heat press to computer |

| 5 | Install the firmware |

| 6 | Restart the heat press |

Keeping your software updated is crucial. It ensures optimal performance and longevity of your Stahls Hotronix Heat Press.

Best Practices For Longevity

Ensuring your Stahls Hotronix Heat Press lasts long means following some best practices. By doing this, you can prevent frequent breakdowns and costly repairs. This section will cover two key areas: Regular Inspections and Proper Storage.

Regular Inspections

Conducting regular inspections helps identify potential issues early. Inspect the heat press for any visible signs of wear or damage.

- Check the heating element for consistent temperature.

- Ensure the pressure settings are accurate.

- Look for any loose or damaged wires.

- Clean the platen surfaces to remove residue.

Maintain a log of all inspections. This helps track the condition over time.

Proper Storage

Storing your Stahls Hotronix Heat Press properly extends its lifespan. Always turn off and unplug the machine before storing.

| Storage Tips | Details |

|---|---|

| Environment | Store in a dry, cool place. |

| Cover | Use a dust cover to protect from debris. |

| Position | Keep the press in an upright position. |

| Temperature | Avoid extreme temperature fluctuations. |

Following these storage tips ensures your heat press remains in optimal condition.

Credit: www.hotronix.com

Frequently Asked Questions

How To Reset Stahls Hotronix Heat Press?

To reset your Stahls’ Hotronix heat press, turn off the machine. Hold down the reset button for 5 seconds. Then, release the button and turn the machine back on.

Why Is My Heat Press Not Reaching Temperature?

Your heat press might not reach temperature due to faulty heating elements, incorrect settings, or a malfunctioning thermostat. Check connections and ensure proper calibration.

Why Is My Power Heat Press Not Heating Up?

Your power heat press may not be heating due to a faulty power source, blown fuse, or damaged heating element. Check connections and replace faulty parts.

How Do You Reset A Heat Press Machine?

To reset a heat press machine, turn off the power. Unplug it from the outlet. Wait 10 minutes. Plug it back in. Turn the power on. Adjust the settings as needed.

Conclusion

Solving issues with your Stahls Hotronix Heat Press can be straightforward. Follow our troubleshooting tips to keep it running smoothly. Regular maintenance is key. Keep an eye on common issues and address them promptly. This will ensure longevity and optimal performance.

Happy pressing!