To troubleshoot Allison Transmission PTO issues, check for proper fluid levels and ensure electrical connections are secure. Inspect the PTO solenoid for wear or damage.

Allison Transmission PTO systems are crucial for powering auxiliary equipment in commercial vehicles. Regular maintenance and timely troubleshooting can prevent costly downtime. Common issues include low fluid levels, faulty electrical connections, and worn-out solenoids. Addressing these problems promptly ensures optimal performance and extends the lifespan of the transmission system.

Technicians should follow a systematic approach, starting with basic checks and progressing to more complex diagnostics. By staying vigilant and proactive, you can maintain the efficiency and reliability of your Allison Transmission PTO, keeping your operations running smoothly.

Credit: www.youtube.com

Common Pto Issues

Allison Transmission PTO (Power Take-Off) systems are reliable and efficient. Yet, they face issues that can disrupt operations. Understanding common PTO issues helps in timely troubleshooting and maintenance.

Loss Of Power

Loss of power is a frequent problem in PTO systems. It can lead to reduced performance and efficiency.

- Hydraulic Leaks: Check for hydraulic fluid leaks. Leaks reduce power and efficiency.

- Worn-Out Gears: Inspect gears for wear and tear. Replace worn gears promptly.

- Electrical Issues: Faulty wiring or connectors can cause power loss. Ensure all connections are secure.

Overheating Problems

Overheating is a serious issue for PTO systems. It can cause long-term damage.

| Cause | Solution |

|---|---|

| Blocked Airflow | Ensure proper ventilation around the PTO unit. |

| Insufficient Lubrication | Check and refill lubricants regularly. |

| Overloaded System | Do not exceed the recommended load capacity. |

Unusual Noises

Unusual noises often indicate underlying problems in the PTO system. These noises need immediate attention.

- Grinding Sounds: Grinding usually means worn gears. Inspect and replace if needed.

- Knocking Noises: Knocking can result from loose components. Tighten all bolts and screws.

- Hissing Sounds: Hissing indicates air or hydraulic leaks. Find and fix leaks quickly.

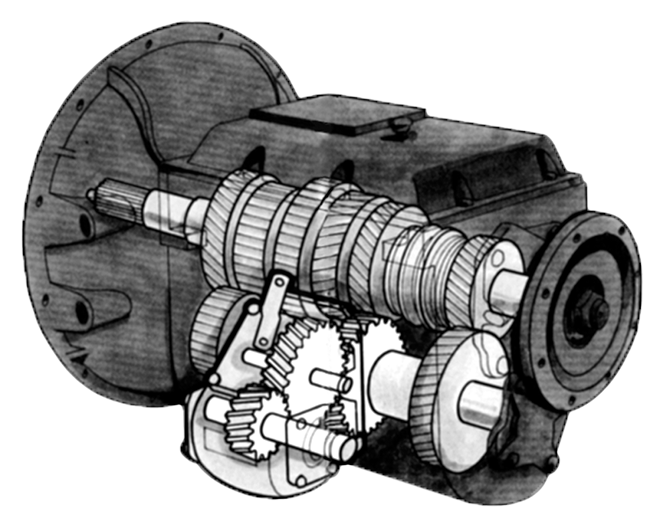

Credit: www.chelseaptopart.com

Initial Checks

Experiencing issues with your Allison Transmission PTO can be frustrating. Performing initial checks can often resolve common problems. This section will guide you through essential steps for troubleshooting.

Inspect Fluid Levels

Start by inspecting the transmission fluid levels. Low fluid can cause poor PTO performance. Use the dipstick to check the fluid. Ensure the fluid is at the correct level. The fluid should be clean and free of debris. Dirty fluid can affect the PTO’s operation.

| Fluid Condition | Action |

|---|---|

| Clean and Proper Level | No action needed |

| Low Level | Add recommended fluid |

| Dirty or Contaminated | Replace fluid |

Check Electrical Connections

Verify all electrical connections to the PTO. Loose connections can cause malfunctions. Ensure connectors are secure and clean. Look for any signs of damage or corrosion. Damaged wires need immediate replacement. Use a multimeter to test the connections. This ensures they are carrying current properly.

- Secure all connections

- Clean connectors

- Check for damage

- Test with a multimeter

Examine Pto Switch

Inspect the PTO switch for proper operation. A faulty switch can prevent the PTO from engaging. Check for any visible damage. Test the switch using a continuity tester. Replace the switch if it fails the test. Ensure the switch is properly connected to the wiring harness.

- Inspect for damage

- Test with a continuity tester

- Replace if necessary

- Check wiring harness connection

Diagnosing Mechanical Failures

Diagnosing mechanical failures in Allison Transmission PTOs can be challenging. Identifying the problem early helps avoid larger issues. This section focuses on diagnosing common mechanical failures.

Gear Wear And Tear

Gear wear and tear is a common issue in Allison Transmissions. Regular inspection is crucial. Look for worn-out teeth or pitting on the gears. These signs indicate excessive wear.

- Check for metal shavings in the oil.

- Listen for unusual noises during operation.

- Inspect gear surfaces for smoothness.

Replace damaged gears promptly. This prevents further transmission problems.

Shaft Misalignment

Shaft misalignment can cause serious issues. Misalignment affects the smooth operation of your PTO. Symptoms include vibrations and unusual noises.

Steps to check for shaft misalignment:

- Visually inspect the shaft alignment.

- Use a dial indicator to measure run-out.

- Check coupling for wear and tear.

Correct any misalignment immediately. Proper alignment extends the life of your transmission.

Broken Seals

Broken seals lead to leaks and contamination. Seals keep fluid in and dirt out. Broken seals cause low fluid levels and increased wear.

Signs of broken seals include:

- Visible oil leaks around the seal area.

- Unusual noise or whining from the transmission.

- Low fluid levels upon inspection.

Replace broken seals quickly. This avoids further damage to the transmission.

| Problem | Symptoms | Solution |

|---|---|---|

| Gear Wear and Tear | Metal shavings, unusual noises | Inspect and replace gears |

| Shaft Misalignment | Vibrations, unusual noises | Check alignment, correct misalignment |

| Broken Seals | Leaks, low fluid levels | Replace seals |

Hydraulic System Troubles

The hydraulic system is crucial for Allison Transmission PTO. When issues arise, it can cause major problems. Below, we explore common hydraulic system troubles and how to address them.

Pump Malfunctions

Pump malfunctions are common in hydraulic systems. A faulty pump can lead to poor performance.

- Check for unusual noises.

- Inspect for leaks.

- Ensure the pump is properly aligned.

If the pump fails, replace it immediately. Regular maintenance can prevent pump malfunctions.

Fluid Contamination

Fluid contamination can damage the hydraulic system. Dirty fluid can clog filters and wear out parts.

To prevent this, follow these steps:

- Use clean, high-quality hydraulic fluid.

- Change the fluid at recommended intervals.

- Regularly inspect and replace filters.

Clean fluid ensures smooth operation and extends the lifespan of your system.

Pressure Issues

Pressure issues can cause the system to malfunction. Too high or too low pressure affects performance.

| Issue | Possible Cause | Solution |

|---|---|---|

| Low Pressure | Leaking hoses | Replace hoses |

| High Pressure | Blocked filters | Clean or replace filters |

Regularly checking and maintaining pressure levels is essential. Proper pressure ensures optimal performance.

Electrical System Diagnostics

Understanding the electrical system of your Allison Transmission PTO is vital. It helps in identifying issues that may cause system failure. This section covers key areas to check during diagnostics.

Fuse And Relay Issues

Fuses and relays play a significant role in the electrical system. They protect and control the power flow. A blown fuse or faulty relay can disrupt the PTO function.

- Locate the fuse box and check for blown fuses.

- Use a multimeter to test the relays.

- Replace any damaged fuses or faulty relays immediately.

Always keep a spare set of fuses and relays in your toolkit. This saves time during emergencies.

Wiring Inspections

Inspecting the wiring is crucial for electrical diagnostics. Damaged wires can cause short circuits and power loss.

- Check for any frayed or broken wires.

- Look for signs of corrosion on the connectors.

- Use electrical tape to insulate minor damages.

- Replace severely damaged wires immediately.

Regularly inspecting the wiring helps in maintaining the system efficiency. It also prevents unexpected breakdowns.

Sensor Failures

Sensors are essential components in the PTO system. They monitor and report various conditions. A faulty sensor can lead to incorrect diagnostics.

| Sensor Type | Function | Common Issues |

|---|---|---|

| Speed Sensor | Monitors rotation speed | Signal loss, incorrect readings |

| Temperature Sensor | Monitors system temperature | Overheating, false alerts |

- Use a diagnostic tool to read sensor outputs.

- Replace any sensor showing inconsistent readings.

Maintaining the sensors ensures accurate system monitoring. It helps in preventing potential failures.

Preventative Maintenance

Maintaining your Allison Transmission PTO can prevent costly repairs. Regular upkeep ensures your equipment runs smoothly. Here are some key steps for effective preventative maintenance.

Regular Inspections

Regular inspections help identify issues early. Check for any leaks, cracks, or unusual noises. Inspect hoses, fittings, and electrical connections. Use a flashlight to see hidden parts. If you find any issues, fix them immediately.

Timely Fluid Changes

Fluid changes keep your transmission in top shape. Check the fluid level often. Follow the manufacturer’s guide for the right fluid type. Use a clean container to avoid contamination. Dispose of old fluid properly. Change the fluid filter as well.

Scheduled Component Replacements

Replace worn-out parts on schedule. This includes gaskets, seals, and bearings. Check the manufacturer’s manual for replacement intervals. Keep a log of replaced parts and dates. This helps track maintenance history.

| Component | Replacement Interval |

|---|---|

| Gaskets | Every 12 months |

| Seals | Every 18 months |

| Bearings | Every 24 months |

Following these steps ensures your Allison Transmission PTO remains efficient. Proper maintenance extends its lifespan. Keep a regular schedule to avoid unexpected breakdowns.

Expert Repair Tips

Maintaining your Allison Transmission PTO can be challenging. Using these expert repair tips can help. These tips focus on using OEM parts, proper torque settings, and professional calibration.

Using Oem Parts

Always use OEM parts for your Allison Transmission PTO repairs. OEM parts ensure compatibility and longevity. They also maintain the integrity of your transmission system. Non-OEM parts may not fit perfectly. They can cause further damage.

OEM parts are tested for quality. They meet the manufacturer’s standards. This ensures your transmission runs smoothly. Using OEM parts can save you money in the long run. They reduce the need for frequent repairs.

Proper Torque Settings

Using the correct torque settings is crucial. Incorrect torque can damage your PTO. It can also lead to safety issues. Always refer to the manufacturer’s manual. The manual provides the precise torque settings.

Use a reliable torque wrench. It ensures the bolts are tightened properly. Over-tightening can strip the threads. Under-tightening can cause parts to loosen. Both can lead to system failure. Follow the torque settings carefully for optimal performance.

Professional Calibration

Regular professional calibration is essential. It ensures your PTO operates at peak efficiency. Calibration adjusts the settings to match the manufacturer’s specifications. This enhances the performance and lifespan of your transmission.

Calibration requires specialized tools and knowledge. It is best done by a certified technician. Regular calibration can prevent unexpected breakdowns. It ensures your PTO performs reliably under various conditions.

Consider scheduling calibration during routine maintenance. This ensures your PTO remains in top condition. Proper calibration can improve fuel efficiency and reduce wear and tear.

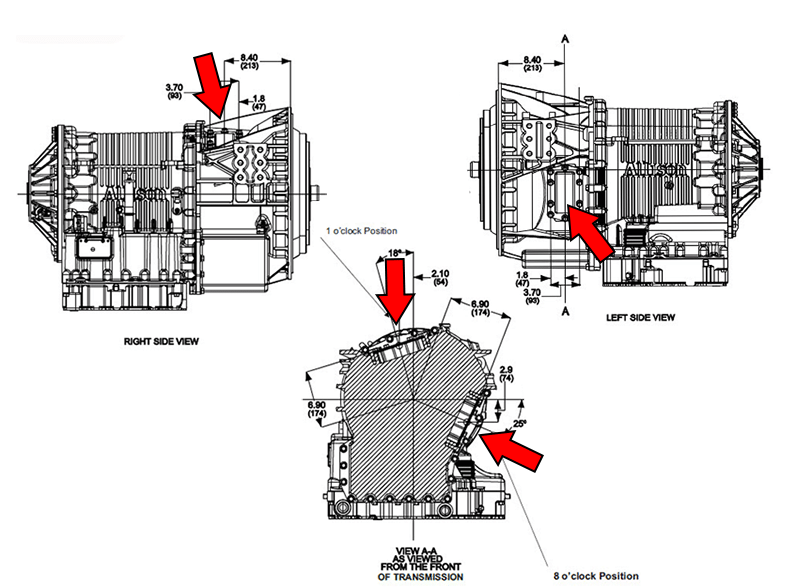

Credit: www.chelseaptopart.com

When To Seek Professional Help

Troubleshooting an Allison Transmission PTO can be tricky. Sometimes, the issues are too complex for a DIY fix. Knowing when to seek professional help is crucial. This can save you time, money, and stress.

Complex Electrical Problems

Dealing with complex electrical problems can be daunting. You might face issues like faulty wiring, blown fuses, or malfunctioning sensors. These problems require specialized tools and expertise. Attempting to fix them without the right knowledge can lead to more damage.

| Common Electrical Issues | Why You Need a Professional |

|---|---|

| Faulty Wiring | Risk of short circuits and further damage |

| Blown Fuses | Need for proper diagnosis and replacement |

| Malfunctioning Sensors | Special tools required for accurate repair |

Severe Mechanical Damage

Severe mechanical damage can be a serious issue. This includes problems like broken gears, damaged shafts, or worn-out bearings. Such issues often require specialized repair techniques. Attempting to fix them yourself can lead to further complications.

- Broken gears require precise alignment.

- Damaged shafts need expert handling.

- Worn-out bearings must be replaced correctly.

Persistent Issues

Some problems keep coming back even after multiple fixes. These persistent issues indicate underlying problems that need a professional touch. Repeatedly trying to fix the same problem can lead to frustration and wasted time.

- Recurring leaks

- Frequent overheating

- Constant transmission slipping

Recognize these signs early and seek professional help. It can prevent bigger issues and ensure your Allison Transmission PTO runs smoothly.

Frequently Asked Questions

How Does Allison Pto Work?

The Allison PTO (Power Take-Off) transfers engine power to auxiliary equipment. It connects directly to the transmission, enabling efficient operation of hydraulic pumps, generators, and other tools.

How Does A Pto Work On An Automatic Transmission?

A PTO on an automatic transmission uses an auxiliary drive to transfer power from the engine to additional equipment. This enables various machinery to operate efficiently without a separate engine.

How Do You Reset The Push Button On An Allison Transmission?

Press and hold the “Mode” button for 10 seconds. Release when the display shows “R” or “Reset”.

What Causes Allison Transmission Limp Mode?

Allison transmission limp mode is caused by sensor issues, low fluid levels, electrical problems, or faulty solenoids. Ensure proper maintenance.

Conclusion

Troubleshooting your Allison Transmission PTO is crucial for optimal performance. Regular maintenance prevents costly repairs. Follow our guide for effective solutions. Proper care extends the lifespan of your transmission. Stay proactive and ensure your vehicle runs smoothly. For more tips and expert advice, keep exploring our blog.