Check for power supply issues and ensure all safety switches are properly engaged. Inspect hydraulic fluid levels and look for leaks.

Cardboard balers are essential for efficient recycling and waste management. Regular maintenance and timely troubleshooting can extend their lifespan. Common issues include power supply problems, hydraulic fluid leaks, and safety switch malfunctions. Keeping an eye on these potential problems helps maintain optimal performance.

Regular inspections and proactive measures ensure the baler operates smoothly. Addressing minor issues before they escalate can save time and money. Proper troubleshooting techniques are crucial for maintaining the efficiency of your cardboard baler. This guide covers the most common troubleshooting steps to keep your equipment running efficiently.

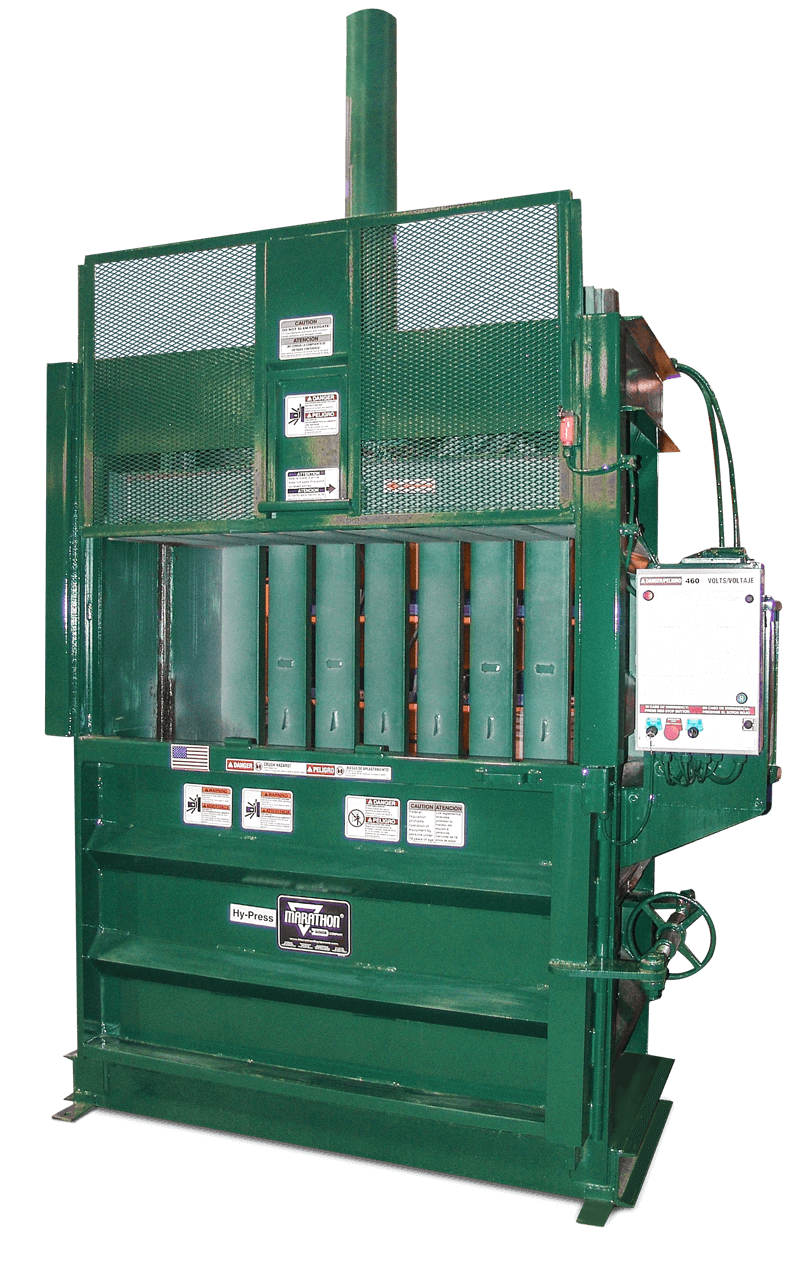

Credit: www.marathonequipment.com

Common Baler Problems

Cardboard balers are essential for efficient waste management. They help in compressing recyclable materials. Yet, like any machinery, they can face issues. Here, we discuss some common problems and solutions.

Bales Not Forming

One frequent issue is bales not forming correctly. This can be due to:

- Improper Loading: Ensure the cardboard is loaded evenly. Uneven loading can prevent proper compression.

- Worn Out Parts: Check for worn-out belts or pulleys. These parts may need replacement.

- Hydraulic Issues: Inspect the hydraulic system. Leaks or low fluid levels can hinder operation.

Machine Jams

Machine jams are another common problem. They can be caused by:

- Overloading: Avoid overloading the baler. Too much material can cause jams.

- Material Type: Ensure only suitable materials are used. Non-cardboard items can jam the machine.

- Maintenance: Regularly clean and maintain the baler. Accumulated debris can lead to jams.

These simple checks can help keep your baler running smoothly. Regular maintenance is key to avoiding problems.

Cardboard Baler Power Supply Issues

Experiencing power supply issues with your cardboard baler can be frustrating. These problems often stem from simple electrical issues. Addressing these can save time and money. Below, we focus on checking electrical connections and circuit breaker troubles.

Checking Electrical Connections

First, ensure all electrical connections are secure. Loose connections can cause intermittent power loss. Follow these steps:

- Turn off the baler and unplug it.

- Inspect the power cord for any visible damage.

- Check the plug and outlet for signs of wear.

- Re-plug the baler and ensure it fits snugly.

If you find any damaged parts, replace them immediately. Clean all connection points to avoid dirt interference.

Circuit Breaker Troubles

Circuit breakers can trip due to overloads or short circuits. Resetting the breaker often solves the issue:

- Locate your circuit breaker panel.

- Identify the breaker connected to the baler.

- If the breaker is tripped, switch it to the “off” position.

- Wait a few seconds, then switch it back to “on”.

If the breaker trips again, there might be a deeper issue. Consider calling a professional electrician to inspect the system.

| Action | Details |

|---|---|

| Inspect Power Cord | Look for visible damage or wear. |

| Check Plug and Outlet | Ensure they are in good condition. |

| Reset Circuit Breaker | Switch off, wait, then switch on. |

These steps help identify and solve common power supply issues. Always ensure safety by turning off power before inspections.

Hydraulic System Failures

Hydraulic system failures are a common issue in cardboard balers. These failures can halt operations and cause downtime. Understanding the reasons behind hydraulic system failures can help in quick troubleshooting and repair. Below, we discuss two major causes: low hydraulic fluid and pump malfunctions.

Low Hydraulic Fluid

Low hydraulic fluid can lead to significant problems in your cardboard baler. Ensuring the fluid level is optimal is crucial for smooth operations.

- Check Fluid Levels: Regularly check the hydraulic fluid levels. Low levels can cause overheating.

- Inspect for Leaks: Look for any visible leaks in the system. Leaks can lead to fluid loss.

- Replace Fluid: Use the recommended hydraulic fluid. Old fluid can lose its effectiveness.

Pump Malfunctions

Pump malfunctions can severely impact the baler’s performance. Identifying and fixing pump issues is essential.

- Listen for Unusual Noises: Strange noises can indicate pump problems. Address these issues immediately.

- Check Pressure Levels: Monitor the hydraulic pressure. Low pressure can signal a failing pump.

- Inspect Pump Components: Regularly inspect the pump for wear and tear. Replace damaged parts promptly.

| Issue | Potential Solution |

|---|---|

| Low Hydraulic Fluid | Check levels, inspect for leaks, replace fluid |

| Pump Malfunctions | Listen for noises, check pressure, inspect components |

Regular maintenance and checks can prevent most hydraulic system failures. Keep your cardboard baler running smoothly by addressing these common issues promptly.

Sensor And Control Problems

Cardboard balers often face issues with sensors and control panels. These problems can disrupt operations and reduce efficiency. Understanding and troubleshooting these issues is essential for smooth functioning.

Faulty Sensors

Faulty sensors are a common issue in cardboard balers. They may cause incorrect readings or fail to detect materials properly. This can lead to inefficient baling and potential machine damage.

Common sensor issues include:

- Dirty sensors: Dust and debris can obstruct sensor function.

- Misaligned sensors: Sensors not positioned correctly may not detect materials.

- Worn-out sensors: Over time, sensors wear out and need replacement.

Regular maintenance can prevent sensor problems. Clean sensors frequently and check alignment.

Control Panel Errors

Control panel errors can halt baler operations. These errors often show up as fault codes or warning lights on the panel.

Common control panel errors include:

| Error Code | Description | Solution |

|---|---|---|

| E01 | Sensor malfunction | Check and clean sensors |

| E02 | Overload | Reduce load and restart |

| E03 | Motor fault | Inspect motor connections |

Follow the manufacturer’s manual for specific error codes. Regular inspection of control panels can prevent unexpected shutdowns.

Use these tips to troubleshoot and fix sensor and control panel issues.

Baler Maintenance Tips

Maintaining your cardboard baler ensures it runs efficiently. Follow these simple tips to keep it in top shape.

Regular Cleaning

Regular cleaning is essential for your baler. Dirt and debris can clog the machine. Clean your baler weekly to avoid problems. Use a brush to remove dust and small particles. Wipe down surfaces with a damp cloth.

- Brush off loose debris.

- Wipe with a damp cloth.

- Inspect for stuck cardboard pieces.

Lubrication

Lubrication keeps your baler running smoothly. Check moving parts monthly. Apply lubricant to gears, chains, and rollers.

| Part | Lubrication Frequency |

|---|---|

| Gears | Monthly |

| Chains | Monthly |

| Rollers | Monthly |

Use the right lubricant for each part. Check the manufacturer’s guide for recommendations.

- Turn off the machine.

- Apply lubricant to gears.

- Apply lubricant to chains.

- Apply lubricant to rollers.

- Restart the machine and test.

Credit: recyclingequipment.com

Safety Precautions

Ensuring safety while troubleshooting a cardboard baler is crucial. Proper safety measures prevent accidents and ensure efficient repairs. Adopting these safety precautions helps maintain a secure work environment.

Proper Training

Every employee must receive proper training on how to operate a cardboard baler. They should understand the machine’s functions and potential hazards. Training should cover:

- Basic operations

- Emergency stop procedures

- Personal protective equipment (PPE)

Regularly update training sessions to include new safety protocols. An informed team is a safe team.

Emergency Procedures

Develop clear emergency procedures for unexpected situations. All employees should know these procedures. Key emergency steps include:

- Shut down the baler immediately

- Evacuate the area

- Contact the supervisor or emergency services

Emergency drills should be conducted regularly. This ensures everyone knows the correct actions during real emergencies.

| Procedure | Action |

|---|---|

| Machine Malfunction | Turn off and report |

| Injury | Provide first aid and call for help |

| Fire | Use fire extinguisher and evacuate |

Professional Help

Cardboard balers are essential for waste management. Sometimes, they need professional help. Knowing when to call a technician is crucial. Choosing the right service is also important.

When To Call A Technician

Cardboard balers show signs of trouble. Look for these common issues:

- Unusual noises during operation

- Hydraulic leaks

- Electrical malfunctions

- Jammed bales

If you see these problems, call a technician. Regular maintenance prevents bigger issues. Always follow the user manual for guidance.

Choosing The Right Service

Not all services are the same. Choose wisely to get the best help. Consider these factors:

| Factor | Importance |

|---|---|

| Experience | Technicians with years of experience |

| Certifications | Certified professionals |

| Customer Reviews | Positive feedback from clients |

| Response Time | Quick and reliable service |

Ask for references if unsure. A good service keeps your baler running smoothly. This saves time and money in the long run.

Credit: globaltrashsolutions.com

Preventive Measures

Ensuring your cardboard baler runs smoothly involves preventive measures. Regular maintenance can save time and money. Below are key preventive steps to consider.

Routine Inspections

Routine inspections are vital for keeping your baler in good condition. Perform daily checks to spot wear and tear. Look for signs of damage on belts and chains. Ensure all bolts and screws are tight.

- Check oil levels and top up if needed.

- Inspect electrical connections for safety.

- Look for hydraulic leaks and address them immediately.

Use a checklist to ensure nothing is missed. This practice helps in early detection of issues.

Upgrading Equipment

Upgrading equipment can enhance baler performance. Modern balers have advanced features. These features reduce downtime and increase efficiency.

Consider the following upgrades:

- Install an automatic oiler for continuous lubrication.

- Upgrade to a digital control panel for better monitoring.

- Use high-quality blades for cleaner cuts.

Investing in upgrades can extend the life of your baler. It also ensures safer operation and reduces maintenance costs.

Frequently Asked Questions

How Do I Reset A Cardboard Baler?

To reset a cardboard baler, turn off the power and follow the manufacturer’s instructions. Press the reset button. Ensure all safety checks are complete before restarting.

How To Unjam A Cardboard Baler?

To unjam a cardboard baler, turn off the machine and disconnect the power. Clear visible obstructions using safety gloves. Restart and test the baler.

What Is The Correct Bale Ejection Process?

To correctly eject a bale, first, stop the machine. Then, disengage the bale chamber. Next, activate the ejection mechanism. Ensure the bale is completely out. Finally, reset the chamber for the next cycle.

Which Of The Following Must Be Done Each Shift Prior To Using The Baler?

Inspect for damage and wear. Check safety guards and devices. Ensure area is clear of obstructions. Verify controls function correctly. Follow lockout/tagout procedures.

Conclusion

Regular maintenance is key to keeping your cardboard baler running smoothly. Address issues promptly to avoid downtime. Use the troubleshooting tips provided to extend the life of your equipment. Proper care ensures efficiency and safety. Always consult the manufacturer’s guide for specific solutions.

Happy baling!