Microsoft Loop and Notion are two popular productivity tools, but they’re designed for different purposes. Microsoft Loop is built for collaboration and task management within the Microsoft 365 ecosystem, making it ideal for teams working closely together. Notion, on the other hand, is a flexible workspace that lets you organize notes, tasks, and databases with customizable templates to suit your workflow.

Both platforms bring unique strengths to the table, and choosing between them depends on your personal or team needs. Understanding how each tool works can help you make a smarter decision.

In this comparison, we’ll break down the key differences and similarities between Microsoft Loop and Notion. By the end, you’ll have a clear idea of which platform is better suited for your productivity and collaboration needs.

Features And Capabilities

When comparing Microsoft Loop and Notion, it’s important to delve into their features and capabilities. Both platforms offer a range of tools and functionalities aimed at enhancing productivity and collaboration. Understanding the distinctive features of each platform can help users make an informed decision about which one suits their needs best.

User Interface

Microsoft Loop boasts a minimalist and intuitive user interface that aligns with the overall Microsoft 365 ecosystem. Its clean design makes it easy for users to navigate and access various features seamlessly. On the other hand, Notion offers a versatile and customizable interface, allowing users to personalize their workspace according to their preferences. Its block-based layout enables users to create and organize content with ease.

Organization And Structure

In terms of organization and structure, Microsoft Loop emphasizes seamless integration with Microsoft applications such as Word, Excel, and PowerPoint. This enables users to manage their content effectively within familiar environments. Notion, on the other hand, provides a robust organizational framework, offering databases, boards, and powerful relational databases to structure information in a granular yet interconnected manner.

Collaboration Tools

Microsoft Loop excels in providing enterprise-grade collaboration tools, including real-time co-authoring, comments, and sharing capabilities. These features are tightly integrated with the Microsoft 365 suite, enhancing team collaboration and communication. Notion, on the other hand, offers a comprehensive set of collaboration tools, enabling teams to ideate, collaborate, and communicate within a single platform. Its flexible sharing and permission settings cater to diverse collaborative workflows.

Integration And Compatibility

When comparing Microsoft Loop and Notion, it’s important to assess their integration and compatibility with third-party apps and mobile access. This aspect often determines the ease of use and accessibility of these tools for individuals and teams.

Third-party Apps

Microsoft Loop offers seamless integration with a wide range of third-party apps, including productivity tools, project management platforms, and communication software. This extensive compatibility allows users to consolidate their workflows and access all relevant information within the Loop interface.

Notion, on the other hand, also provides integration with various third-party apps, albeit with a somewhat narrower scope in comparison to Microsoft Loop. Users can leverage integrations with popular tools such as Google Drive, Slack, and Trello, but the ecosystem may not be as comprehensive as that of Loop.

Mobile Access

In terms of mobile access, Microsoft Loop boasts robust compatibility across devices and operating systems. Whether accessed through smartphones, tablets, or desktops, users can seamlessly transition between different platforms while maintaining a consistent user experience. This enables enhanced flexibility and productivity for on-the-go professionals.

Similarly, Notion offers comprehensive mobile access, allowing users to stay connected and productive while on the move. The mobile app enables seamless synchronization with the desktop interface, ensuring that users can access and modify their content regardless of their location or device.

Pros And Cons

When it comes to productivity and collaboration tools, Microsoft Loop and Notion have become popular choices among individuals and teams. Both platforms offer a range of features and flexibility that cater to different user needs. In this article, we will explore the pros and cons of each tool, helping you make an informed decision.

Microsoft Loop Pros

Microsoft Loop offers several advantages that make it an appealing choice for many users:

- Integration with Microsoft Suite: If you are already using Microsoft applications such as Word, Excel, and PowerPoint, using Microsoft Loop ensures seamless integration and compatibility across the suite.

- Real-time Collaboration: With Microsoft Loop, multiple team members can work on a document simultaneously, making it an ideal tool for collaborative projects.

- Robust Security: Microsoft Loop provides advanced security features, including data encryption, access controls, and compliance standards, keeping your sensitive information protected.

- Version Control: The version control feature in Microsoft Loop enables you to track changes, revert to previous versions, and collaborate efficiently, particularly in large teams.

Notion Pros

Notion also offers several benefits that contribute to its increasing popularity:

- Flexible Workspace: Notion provides a highly customizable workspace with its drag-and-drop interface, making it easy to organize and structure your content according to your preferences.

- Database Capabilities: With Notion’s extensive database functionality, you can create databases, tables, and linked properties to manage and analyze your data effectively.

- Wide Variety of Templates: Notion offers a wide range of pre-designed templates for various use cases, including project management, to-do lists, and meeting agendas, helping you save time and streamline your work.

- Third-Party Integrations: Notion supports integration with popular third-party applications like Google Drive, Trello, and Slack, allowing you to connect and centralize your workflow in one place.

Microsoft Loop Cons

Despite its strengths, Microsoft Loop has a few drawbacks that may affect its suitability for certain users:

- Learning Curve: Microsoft Loop can be complex and require some time to get used to, particularly for new users who are not familiar with the Microsoft Suite.

- Platform Limitations: As a web-based tool, Microsoft Loop’s functionality may be limited and less customizable compared to desktop applications.

- Pricing: Microsoft Loop is part of the Microsoft 365 suite, and while it offers a free version, some advanced features may require a subscription, which may not be suitable for all budgets.

Notion Cons

Despite its great features, Notion has a few limitations that may impact certain users:

- Steep Learning Curve: Notion’s extensive functionality can be overwhelming for new users, requiring time and effort to learn and customize the platform to meet your specific needs.

- Limited Formatting Options: While Notion offers basic formatting features, it may not satisfy users requiring advanced formatting options or complex document layouts.

- Collaboration Limitations: While Notion allows real-time collaboration, it may not be as robust as other tools like Microsoft Loop, especially for large teams working simultaneously on complex projects.

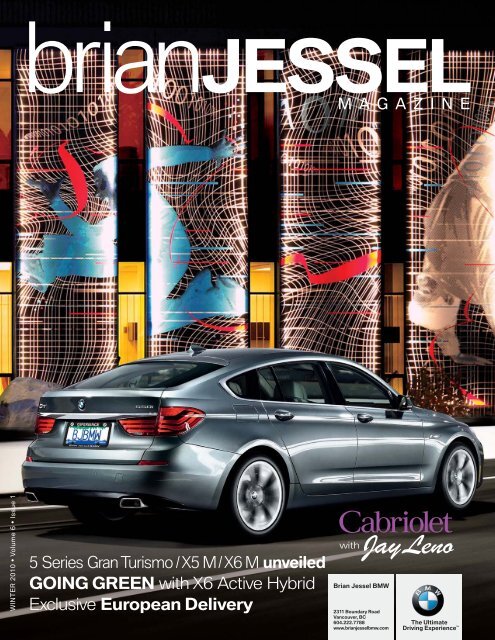

Credit: www.yumpu.com

Frequently Asked Questions

What Are The Key Differences Between Microsoft Loop And Notion?

Microsoft Loop and Notion are both productivity tools, but they have some key differences. Microsoft Loop is a collaborative workspace that integrates with other Microsoft apps, providing a seamless experience for teams. Notion, on the other hand, is a versatile tool that allows you to create notes, documents, and databases all in one place.

Can Microsoft Loop And Notion Be Used Together?

Yes, Microsoft Loop and Notion can be used together. While they have different feature sets, they both excel in helping teams collaborate and stay organized. You can use Microsoft Loop for seamless integration with other Microsoft apps, and Notion for its flexibility in creating and organizing content.

Which Tool Is Better For Remote Teams – Microsoft Loop Or Notion?

Both Microsoft Loop and Notion are great tools for remote teams, but it depends on your team’s specific needs. Microsoft Loop’s integration with other Microsoft apps makes it ideal for teams already using Microsoft products. Notion’s versatility and ease of use make it a great choice for teams looking for a flexible and customizable solution.

Overall, it’s best to evaluate your team’s unique requirements before choosing the tool that suits you best.

Can I Migrate My Existing Projects From Notion To Microsoft Loop?

Yes, you can migrate your existing projects from Notion to Microsoft Loop. Both tools have import/export features that allow you to transfer data between them. However, it’s important to note that there may be some formatting differences between the two platforms, so it’s advisable to double-check your migrated content to ensure everything is in order.

Conclusion

Overall, both Microsoft Loop and Notion offer various features and functionalities for efficient team collaboration and task management. While Microsoft Loop excels in integrating seamlessly with the Microsoft 365 suite and is ideal for large organizations, Notion stands out for its flexible and customizable interface, making it a popular choice for individuals and smaller teams.

Ultimately, the decision between the two depends on your specific needs and preferences. So, consider evaluating your requirements and explore the strengths of each platform to make an informed decision that enhances your productivity and workflow.